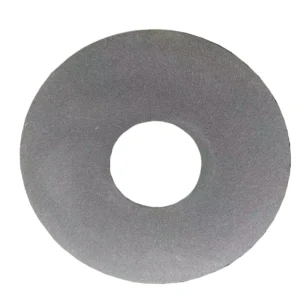

High-Precision Surface Grinding Wheel for Metal and Tool Grinding

Product Description

The surface grinding wheel with high-performance abrasive, usually used for surface finishing and precision grinding of metal components, tools, and molds.

Made with high quality abrasive, this wheel with strong cutting ability, stable dimensional accuracy, and extended service life, suitable for flat surface grinding, finishing of mold surfaces, and grinding of small to medium metal components.

Here is usually application: automotive, machinery, tool, and mold industries. It performs reliably on surface grinding machines, CNC grinders, and conventional grinding machines.

We can customized according to customer’s application, ensuring optimal performance for various materials, including carbon steel, alloy steel, stainless steel, and cast iron.

Applications

Surface grinding of metal plates and blocks

Tool and die grinding

Mold finishing and precision component grinding

Automotive and machinery parts surface processing

Product Advantages

- High-Precision Grinding

Ensures flatness, parallelism, and consistent surface finish. - Strong Vitrified Bond

Provides long-lasting stability and form retention. - Efficient Heat Dissipation

Reduces grinding burns and improves surface quality. - Wide Material Compatibility

Suitable for steel, stainless steel, alloy, and cast iron parts. - Customizable Specifications

Grit size, hardness, structure, and wheel dimensions can be tailored.

FAQ

Q1: Do you have experience in international business?

A: Yes. We are a manufacturer of grinding wheels with many years of experience in international markets. Our products have been exported to different regions, and we maintain long-term cooperation with overseas customers.

Q2: How can I choose the right grinding wheel?

A: You can provide information about your application, such as the workpiece material, grinding process and machine type. Our technical team will recommend a suitable grinding wheel.

If you already have drawings or specifications, we can also produce according to your requirements.

Q3: How do you ensure the quality of your grinding wheels?

A: All grinding wheels are manufactured under controlled processes and inspected before delivery. We focus on stable performance, dimensional accuracy and consistent quality for industrial grinding applications.

Q4: Do you offer customized grinding wheels?

A: Yes. We offer customized grinding wheels with different sizes, bores, abrasives and grit specifications to meet various industrial needs.

Q5: How about after-sales service?

A: If any quality-related issues occur, please contact us with detailed feedback. We will analyze the application conditions and provide technical support or suitable solutions.