Vitrified Grinding Wheel for Crankshaft

Product Description

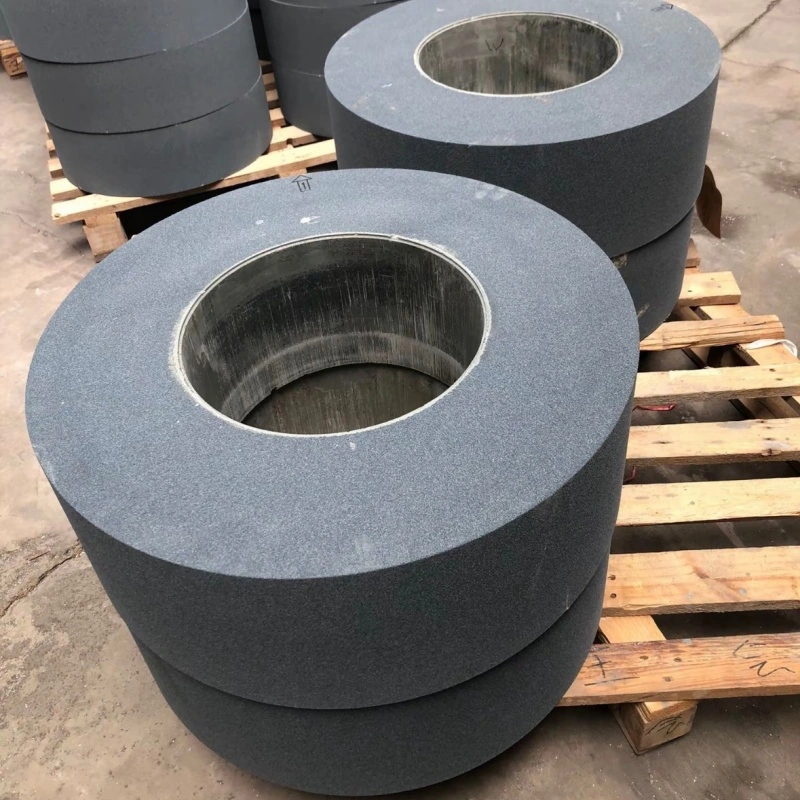

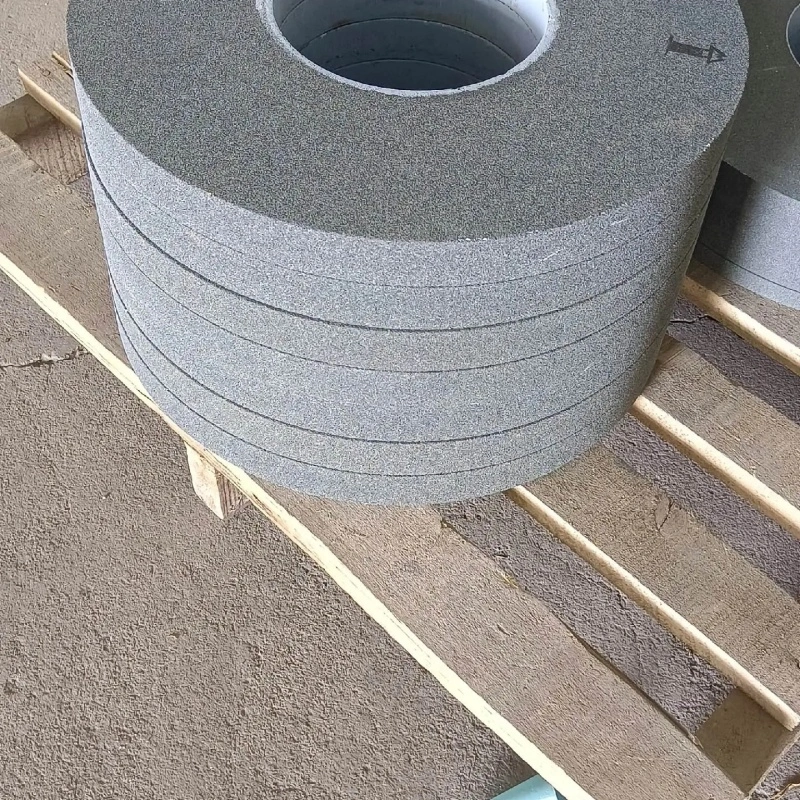

The Vitrified Grinding Wheel for Crankshaft Grinding is specially designed for high-precision and heavy-duty grinding of crankshaft main journals and crank pins.

Manufactured with premium abrasives, this grinding wheel provides excellent form retention, stable cutting performance, and consistent surface finish during continuous grinding operations.

It is widely used in automotive engines, marine engines, diesel generators, and heavy machinery repair workshops, making it an ideal choice for both OEM production and crankshaft regrinding applications.

We also supply surface grinding wheel with custom sizes and specifications.

Specifications

Abrasive: A/ PA/ SG/ WA/ WAA/ C

Grit Size: 36#, 46#, 60#, 80#, 100# (customizable)

Hardness: J – P (customizable)

Bond: Vitrified (V)

Wheel Shape: Straight wheel (Type 1)

Application Machine: Surface grinding machines

Specifications can be customized according to your grinding requirements.

|

Diameter (mm) |

Hole(mm) | Thickness(mm) | Abrasive | Grit |

Bond |

| 250 | 32 | 25/35 | A/ WA/ PA/ SA/ SG/ C/ GC/ Mixed | 36# / 46# / 60# / 80# / 100# / 120# | Vitrified Resined |

| 300 | 75/76.2/127 | 32/40/50 | |||

| 350 | 75/76.2/127/203 | 32/40/50 | |||

| 400 | 127/160/203 | 32/40/50/63 | |||

| 450 | 203/254/305 | 32/40/50/63/75 | |||

| 500 | 305 | 32/40/50/63/75/100 | |||

| 600 | 305 | 32/40/50/63/75/100/125 | |||

| 650 | 305 | 33/40 | |||

| 750 | 305 | 22/25/28/33/40/43/58/61/67/86 | |||

| 900 | 305 | 22/25/28/32/33/38/40/42/43/47/52/55/58/61/72/75/78/82/90 | |||

| 1065 | 304.8 | 22/25/32/38/42/47/52/55 | |||

| 1100 | 305 | 25/32/33/38/40/43/55/58/61/72/75/82/86/90 | |||

| 1200 | 305 | 120/150 | |||

| 1250 | 305 | 42/75/80 | |||

| 1400 | 305 | 80/86/120 | |||

| 1600 | 305 | 80/86/120 | |||

| 1600 | 900 | 86/90/120 | |||

| 1800 | 305 | 90/120 |

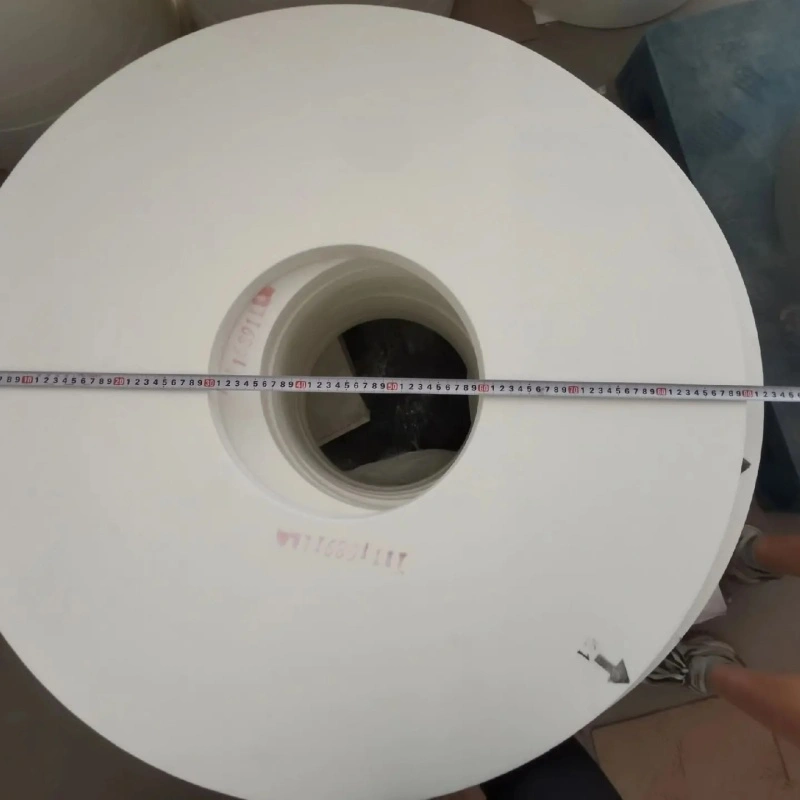

Packaging & Delivery

Strong export-standard carton and pallet.

OEM label and private branding available

Stable supply for bulk orders

FAQ

1. How do you choose the correct bond type for crankshaft grinding?

You usually choose a vitrified bond for crankshaft grinding because it delivers high thermal stability, controlled porosity for better coolant flow, and a reduced risk of grinding burn.

You may use resin bond wheels in specific light-duty applications, but vitrified bond wheels perform better in heavy-duty crankshaft grinding.

2. Can you use one grinding wheel for both rough and finish grinding?

In most cases, you should use separate grinding wheels for different grinding stages:

- You use coarser grit wheels for rough grinding

- You use finer grit wheels for finish grinding

This approach improves surface finish, extends wheel life, and ensures more stable grinding performance.

3. How often should you dress a crankshaft grinding wheel?

You should dress the grinding wheel based on actual grinding conditions. In general:

- Dress the wheel when surface finish begins to deteriorate

- Increase dressing frequency during rough grinding

- Use diamond or rotary dressers to maintain a consistent wheel profile

Proper dressing improves cutting efficiency and prevents wheel glazing.

4. What causes grinding burn during crankshaft grinding?

Grinding burn occurs when you use an incorrect grit size or bond hardness, supply insufficient coolant, apply excessive infeed or feed rate, or allow the wheel to become dull or glazed.

You can significantly reduce burn risk by selecting the correct wheel specification and maintaining proper dressing.

5. Can you use crankshaft grinding wheels for camshaft grinding?

Yes. You can use many crankshaft grinding wheels for camshaft grinding as long as the wheel specification—abrasive, grit size, and bond—matches the camshaft material and grinding conditions.

6. Can you customize crankshaft grinding wheels?

Yes. You can customize crankshaft grinding wheels in terms of:

- Outer diameter, thickness, and bore size

- Abrasive type and grit size

- Wheel hardness and structure

Customization ensures optimal performance on specific grinding machines and applications.