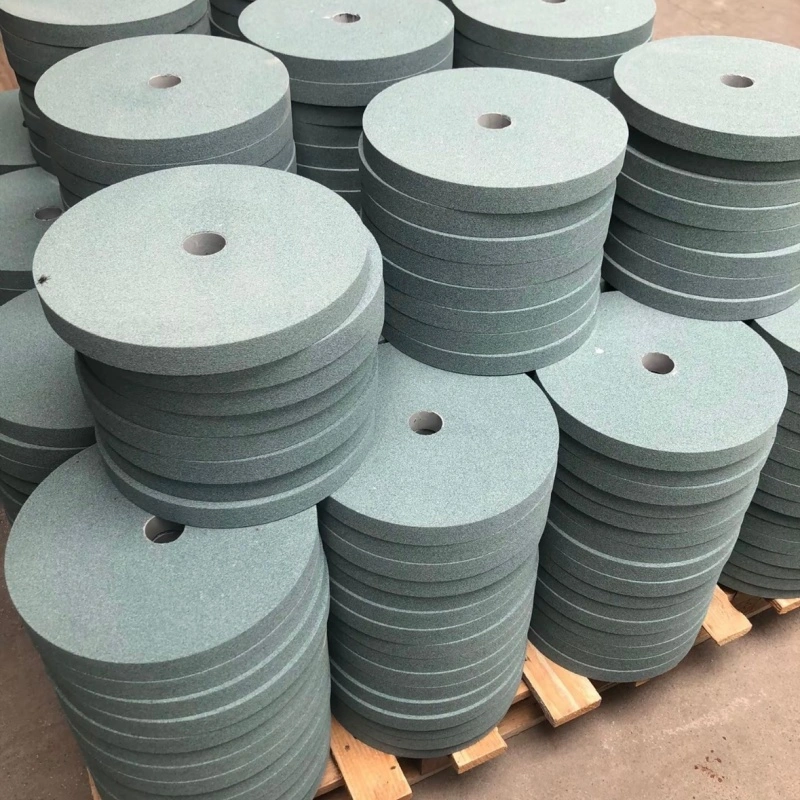

Green Silicon Carbide Grinding Wheel for Hard Material Grinding

Product Description

The green silicon carbide grinding wheel is specially designed for grinding hard and brittle materials that require sharp cutting ability and low grinding force.

The green silicon carbide grinding wheel with provides fast cutting performance, excellent sharpness, and stable grinding results.

Compared with aluminum oxide wheels, the green silicon carbide grinding wheel features higher hardness and sharper grain edges, making it ideal for precision grinding of carbide tools and non-ferrous materials.

Specifications

Abrasive: Aluminum Oxide (A)

Bond: Vitrified (V) / Resined (B)

Compared with resinoid bonds, a vitrified bond grinding wheel offers better form holding and thermal stability.

Grit Size: 36#, 46#, 60#, 80#, 100# (customizable)

Hardness: J – P (customizable)

Wheel Shape: Straight wheel (Type 1)

Diameter: 150 – 600 mm (custom sizes available)

Application Machine: Surface grinding machines

Specifications can be customized according to your grinding requirements.

|

Diameter (mm) |

Hole(mm) | Thickness(mm) | Abrasive | Grit |

Bond |

| 250 | 32 | 25/35 | A/ WA/ PA/ SA/ SG/ C/ GC/ Mixed | 36# / 46# / 60# / 80# / 100# / 120# | Vitrified Resined |

| 300 | 75/76.2/127 | 32/40/50 | |||

| 350 | 75/76.2/127/203 | 32/40/50 | |||

| 400 | 127/160/203 | 32/40/50/63 | |||

| 450 | 203/254/305 | 32/40/50/63/75 | |||

| 500 | 305 | 32/40/50/63/75/100 | |||

| 600 | 305 | 32/40/50/63/75/100/125 | |||

| 650 | 305 | 33/40 | |||

| 750 | 305 | 22/25/28/33/40/43/58/61/67/86 | |||

| 900 | 305 | 22/25/28/32/33/38/40/42/43/47/52/55/58/61/72/75/78/82/90 | |||

| 1065 | 304.8 | 22/25/32/38/42/47/52/55 | |||

| 1100 | 305 | 25/32/33/38/40/43/55/58/61/72/75/82/86/90 | |||

| 1200 | 305 | 120/150 | |||

| 1250 | 305 | 42/75/80 | |||

| 1400 | 305 | 80/86/120 | |||

| 1600 | 305 | 80/86/120 | |||

| 1600 | 900 | 86/90/120 | |||

| 1800 | 305 | 90/120 |

Applications

1. Surface grinding of carbon steel & alloy steel.

2. Grinding of tool steel and hardened steel (after heat treatment).

3. Precision grinding for dies, molds, plates, and mechanical components.

4. General surface grinding in machine shops and workshops.

5. Cylinder liners, crankshafts and camshafts grinding.

6. Auto parts, shipbuilding, engine repair workshop.

7. Rough grinding with high material removal.

For surface finishing operations, a surface grinding wheel provides excellent flatness and consistency.

Packaging & Delivery

Strong export-standard carton and pallet.

OEM label and private branding available

Stable supply for bulk orders

Product Advantages

- High-Precision Grinding

Ensures flatness, parallelism, and consistent surface finish. - Strong Vitrified Bond

Provides long-lasting stability and form retention. - Efficient Heat Dissipation

Reduces grinding burns and improves surface quality. - Wide Material Compatibility

Suitable for steel, stainless steel, alloy, and cast iron parts. - Customizable Specifications

Grit size, hardness, structure, and wheel dimensions can be tailored.

FAQ

Q1: Do you have experience in international grinding wheel business?

A: Yes. As a professional grinding wheel manufacturer, we have many years of experience in international business. Our vitrified grinding wheels have been exported to multiple countries and regions worldwide. Moreover, we maintain long-term cooperation with overseas customers in various industrial grinding applications.

Q2: How can I choose the right grinding wheel for my application?

A: To choose the right grinding wheel, you can first provide details such as the workpiece material, grinding process, and machine type. Based on this information, our technical team will recommend a suitable industrial grinding wheel. In addition, if you already have drawings or specifications, we can produce customized grinding wheels according to your requirements.

Q3: How do you ensure the quality of vitrified grinding wheels?

A: All vitrified grinding wheels are manufactured under strictly controlled production processes. Before shipment, each grinding wheel is inspected to ensure stable performance, accurate dimensions, and consistent quality. As a result, our products are reliable for long-term industrial grinding operations.

Q4: Do you offer customized grinding wheel solutions?

A: Yes. As an experienced grinding wheel supplier, we offer customized grinding wheels with different sizes, bores, abrasive types, and grit specifications. Therefore, we can provide grinding wheel solutions tailored to various industries and applications.

Q5: What after-sales service do you provide for grinding wheels?

A: If any quality-related issues occur with our grinding wheels, please contact us with detailed application feedback. After analyzing the grinding conditions, our technical team will provide professional technical support or suitable solutions to ensure smooth and efficient grinding performance.