Crankshaft Grinding Wheel

Product Description

A crankshaft grinding wheel is a specialized grinding wheel used for precision machining and reconditioning of crankshafts. It is typically manufactured with vitrified bond to ensure high rigidity, accurate profile retention, and effective heat dissipation during grinding.

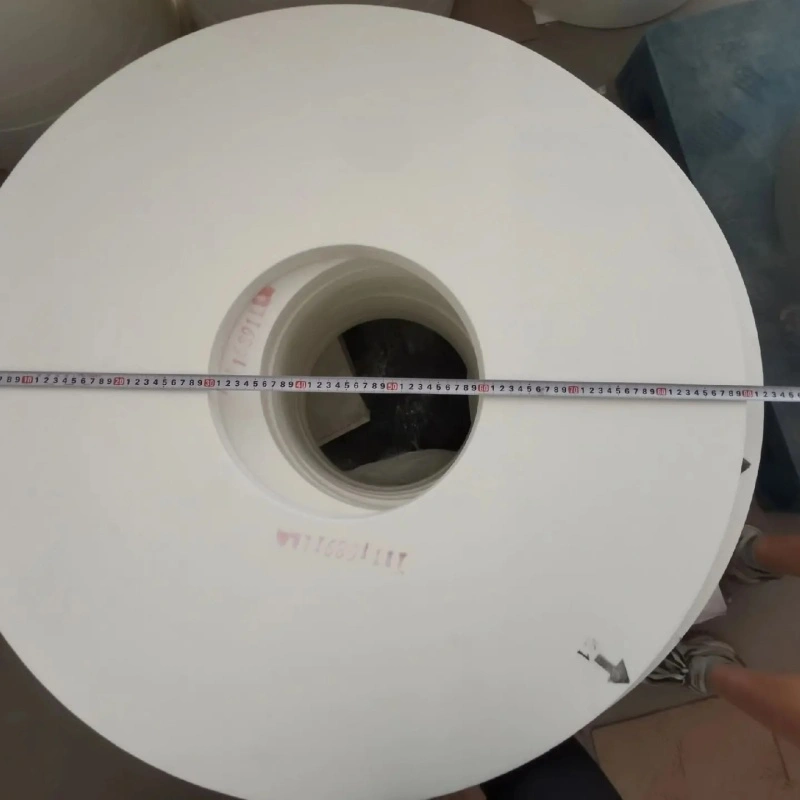

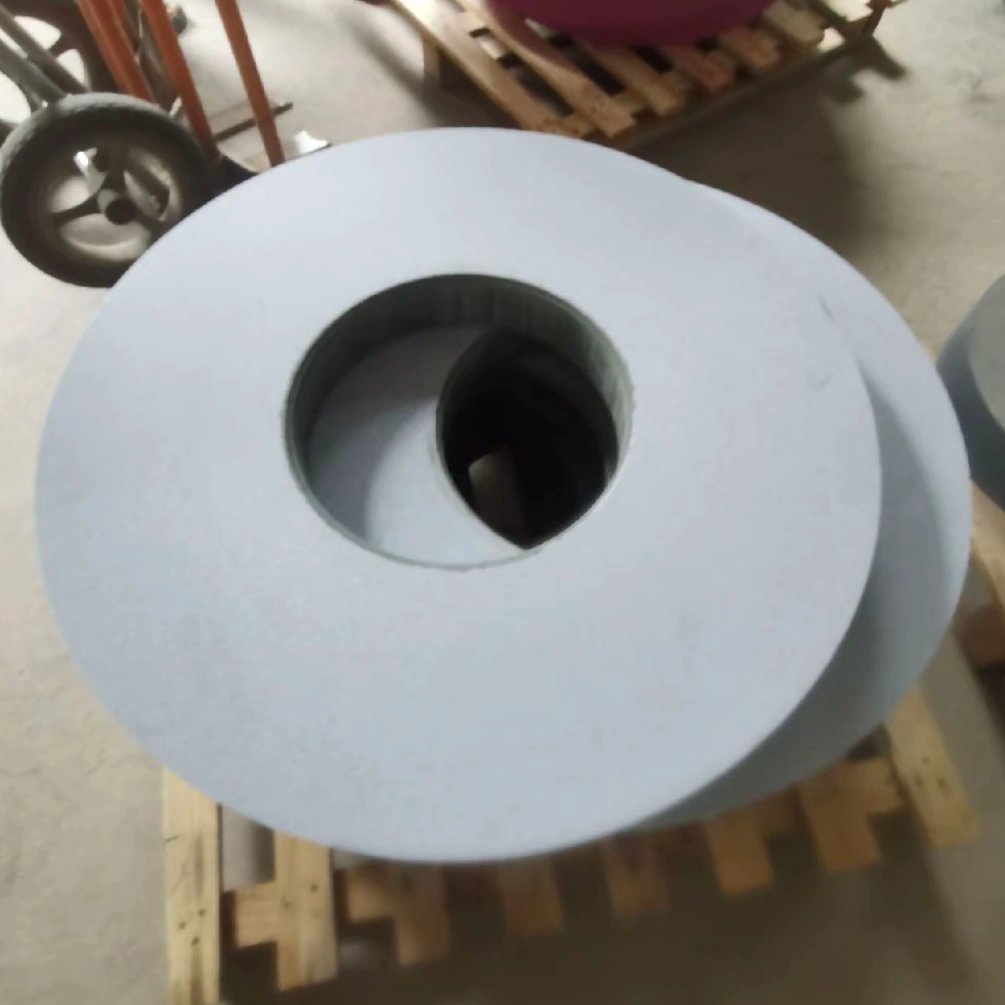

Avaliable Size & Specifications

Wheel Shape: Straight wheel (Type 1)

Common sizes available:

• Ø500 × Ø203.2 × 50 mm

• Ø600 × Ø304.8 × 75 mm

• Ø710 × Ø304.8 × 60 mm

• Ø900 × Ø304.8 × 18 mm

• Ø900 × Ø304.8 × 20 mm

• Ø915 × Ø304.8 × 25 mm

Max Speed: 35 m/s

Abrasive: A/ PA/ SG/ WA/ WAA/ C

Grit: 36#, 46#, 60#, 80#(customizable)

Hardness: J – P (customizable)

Bond: Vitrified (V)

Application: Crankshaft Grinding Wheels for engine repair and industrial applications.

Specifications can be customized according to your grinding requirements.

|

Diameter (mm) |

Hole(mm) | Thickness(mm) | Abrasive | Grit |

Bond |

| 250 | 32 | 25/35 | A/ WA/ PA/ SA/ SG/ C/ GC/ Mixed | 36# / 46# / 60# / 80# / 100# / 120# | Vitrified Resined |

| 300 | 75/76.2/127 | 32/40/50 | |||

| 350 | 75/76.2/127/203 | 32/40/50 | |||

| 400 | 127/160/203 | 32/40/50/63 | |||

| 450 | 203/254/305 | 32/40/50/63/75 | |||

| 500 | 305 | 32/40/50/63/75/100 | |||

| 600 | 305 | 32/40/50/63/75/100/125 | |||

| 650 | 305 | 33/40 | |||

| 750 | 305 | 22/25/28/33/40/43/58/61/67/86 | |||

| 900 | 305 | 22/25/28/32/33/38/40/42/43/47/52/55/58/61/72/75/78/82/90 | |||

| 1065 | 304.8 | 22/25/32/38/42/47/52/55 | |||

| 1100 | 305 | 25/32/33/38/40/43/55/58/61/72/75/82/86/90 | |||

| 1200 | 305 | 120/150 | |||

| 1250 | 305 | 42/75/80 | |||

| 1400 | 305 | 80/86/120 | |||

| 1600 | 305 | 80/86/120 | |||

| 1600 | 900 | 86/90/120 | |||

| 1800 | 305 | 90/120 |

Applications

• Automotive crankshaft regrinding

• Diesel engine crankshaft repair

• Heavy-duty engine rebuilding

• CNC crankshaft grinding machines

• Engine remanufacturing workshops

Packaging & Delivery

Strong export-standard carton and pallet.

OEM label and private branding available

Stable supply for bulk orders

Key Advantages

• High form retention for precise crankshaft journals

• Excellent thermal stability for continuous grinding

• Consistent surface roughness control

• Suitable for steel and alloy crankshafts

• Long service life in automotive and industrial use

FAQ

1. Which grinding wheel do you use for crankshaft grinding?

You typically use vitrified bonded grinding wheels for crankshaft grinding because they maintain wheel shape, resist thermal deformation, and deliver stable performance in both rough and finish grinding operations.

2. Which abrasive works best for crankshaft grinding?

You should select the abrasive based on the crankshaft material:

White Aluminum Oxide (WA/A) works best for alloy steel and forged steel crankshafts

Green Silicon Carbide (GC) performs well on cast iron crankshafts

The correct abrasive reduces wheel wear and minimizes grinding burn.

3. What grit size should you choose for crankshaft grinding wheels?

You commonly choose:

36–46 grit for rough grinding and high stock removal

60 grit for semi-finish grinding

80 grit for finish grinding when you need a finer surface finish

Your final choice depends on material hardness and surface quality requirements.

4. What sizes do the crankshaft grinding wheels come in?

Manufacturers commonly supply outer diameters of Ø750, Ø800, Ø900, Ø915, and Ø1000 mm.

You can also customize wheel thickness and bore size (such as 304.8 mm) to match your grinding machine.

5. What causes grinding burn during crankshaft grinding?

Grinding burn occurs when you use an incorrect wheel specification, apply excessive infeed, supply insufficient coolant, or neglect proper dressing.

You can significantly reduce burn risk by selecting the correct grit size, vitrified bond, and dressing method.