Green Silicon Carbide grinding wheels (GC) are widely used in precision grinding applications, where high hardness, sharp cutting performance, and an excellent surface finish are required. As a result, they are especially suitable for demanding industrial grinding operations.

Compared with conventional abrasives, green silicon carbide grinding wheels provide significantly higher cutting efficiency when machining hard and brittle materials. Moreover, their sharp and self-sharpening abrasive structure ensures consistent performance, making GC grinding wheels an essential choice across a wide range of industrial sectors.

Therefore, in this guide, we will explore what green silicon carbide grinding wheels, their key applications, advantages, and how to select the right specification for your grinding needs.

Firstly, what Is a Green Silicon Carbide Grinding Wheel?

GC abrasive compared with black silicon carbide, in short, green silicon carbide has the following advantages:

- Higher purity

- Sharper cutting edges

- Greater hardness

- Better self-sharpening ability

Therefore, these characteristics make it ideal for precision grinding and finishing operations.

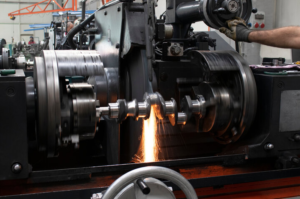

Secondly, key Applications of Green Silicon Carbide Grinding Wheel

GC grinding wheels are especially suitable for grinding hard, brittle, and non-ferrous materials. For example:

- Tungsten carbide and cemented carbide tools

- Optical glass and technical ceramics

- Quartz, stone, and refractory materials

- Non-ferrous metals such as aluminum, copper, and brass

- Carbide cutting tools and inserts

Besides, they are commonly used in:

- Tool sharpening

- Surface grinding

- Cylindrical grinding

- Precision finishing and polishing

Next, advantages of Green Silicon Carbide Grinding Wheels

1. Exceptional Cutting Sharpness

Green silicon carbide abrasive fracture easily, continuously exposing new sharp edges. This ensures fast material removal with reduced grinding force.

2. Excellent Heat Dissipation

The abrasive structure helps minimize heat buildup during grinding, reducing the risk of thermal damage and surface burns.

3. High Hardness and Wear Resistance

with superior hardness compared to conventional abrasives, GC grinding wheels maintain stable performance even under demanding conditions.

4. Superior Surface Finish

In addition, green silicon carbide wheels deliver smooth and consistent surface quality, especially on brittle materials where precision is critical.

Then, how to Choose the Right Green Silicon Carbide Grinding Wheel

Therefore, selecting the correct grinding wheel depends on several factors:

• Grit

- Coarse grits (16–46): Rapid stock removal

- Medium grits (60–80): General grinding

- Fine grits (100–220): Precision finishing

• Bond Type

- Vitrified bond: High rigidity and precision

- Resin bond: Better shock absorption and surface finish

- Rubber bond: Fine polishing and control

• Grinding Wheel Shape & Size

Choose the wheel type (straight, cup, dish, or segmented) based on your machine and application requirements.

After that, custom Green Silicon Carbide Grinding Wheel for Industrial Use

For industrial buyers, customization is often essential. As a result, green silicon carbide grinding wheels can be tailored in terms of:

- Dimensions and shapes

- Grit size and structure

- Bond type and hardness

- Application-specific performance requirements

Customized solutions help improve efficiency, extend wheel life, and achieve better grinding results.

Conclusion

In conclusion, green silicon carbide grinding wheels are a reliable and efficient solution for grinding hard, brittle, and non-ferrous materials, especially where precision and surface quality matter most. When properly selected, with the right specifications and bond type, they can significantly enhance productivity, improve grinding efficiency, and deliver consistent performance in demanding industrial applications.

Therefore, if you are looking for high-quality or custom green silicon carbide grinding wheels, choosing an experienced and reliable manufacturer can truly make all the difference in terms of performance, consistency, and long-term cost efficiency.