Vitrified Grinding Wheel Manufacturer

Product Description

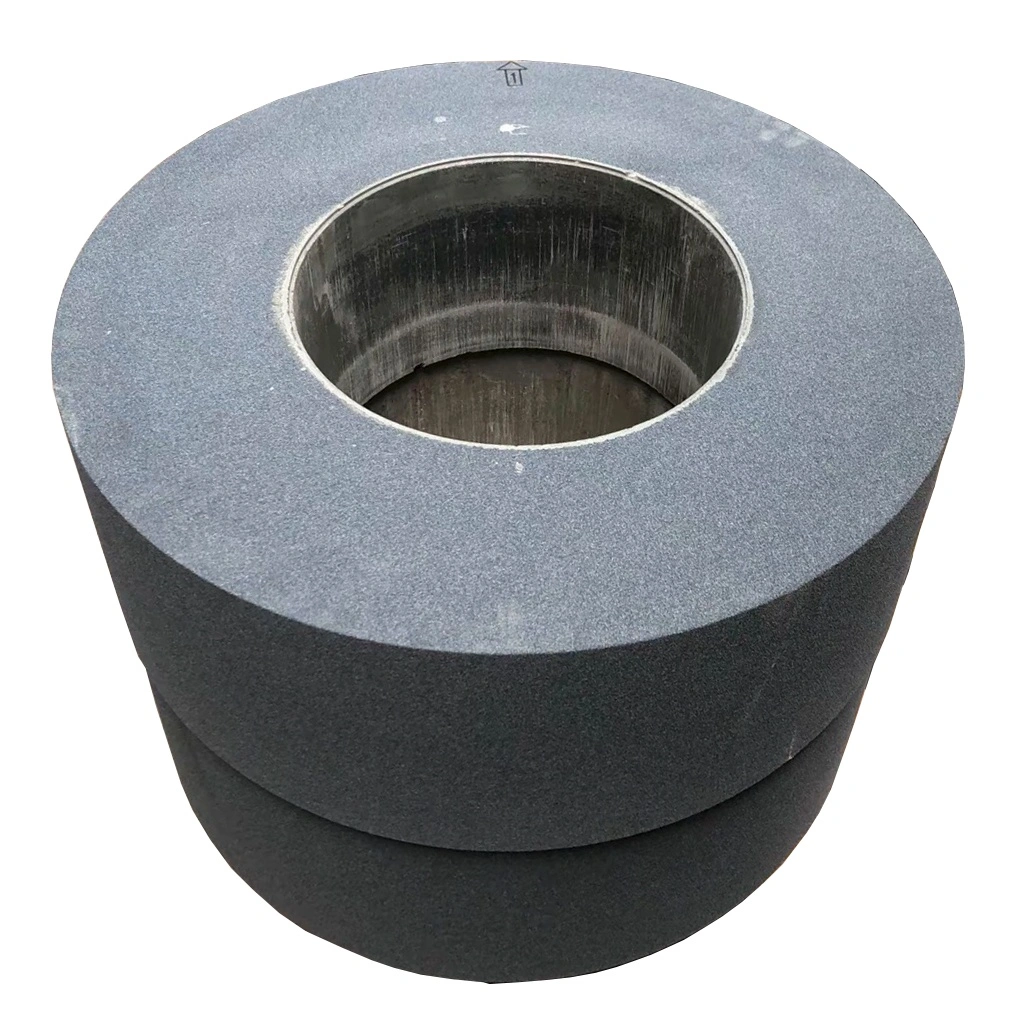

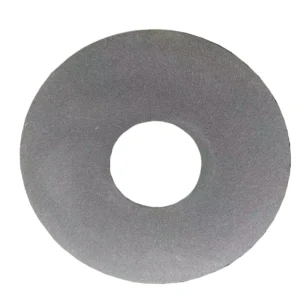

As an experienced vitrified grinding wheel manufacturer, we design and produce grinding wheels with a rigid ceramic bond that ensures excellent shape retention and consistent cutting performance.

Moreover, vitrified grinding wheels provide superior heat resistance, which helps maintain workpiece accuracy during long grinding cycles.

In addition, our vitrified bonded grinding wheels deliver sharp cutting action and controlled wear. As a result, operators achieve stable grinding efficiency, reduced vibration, and improved surface finish.

Because of these advantages, vitrified grinding wheels are ideal for both rough grinding and precision finishing operations.

Furthermore, we manufacture grinding wheels using carefully selected abrasives such as aluminum oxide, white aluminum oxide, and silicon carbide, allowing us to match wheel performance to different materials and grinding conditions.

Typical Applications

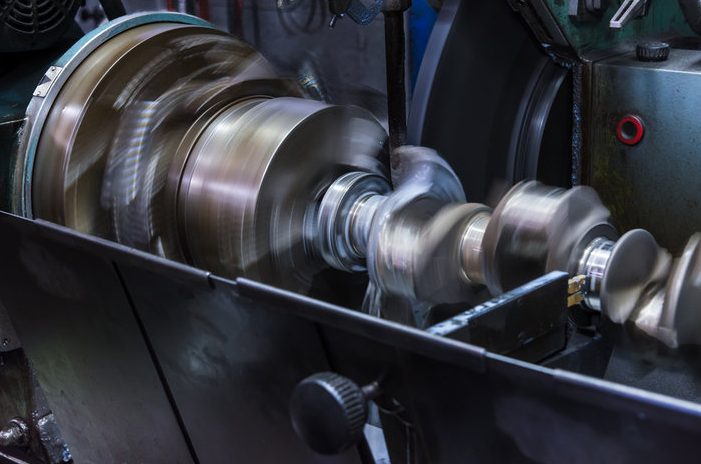

Our vitrified grinding wheels are suitable for a wide range of industrial grinding applications, including:

-

Shaft grinding and crankshaft grinding

-

Cylindrical and external grinding

-

Surface grinding

-

Tool and die grinding

-

Engine component grinding and repair workshops

Therefore, they are widely used in automotive, marine engine repair, machinery manufacturing, steel processing, and maintenance workshops.

Available Specifications

As a flexible vitrified grinding wheel manufacturer, we offer both standard and customized specifications:

-

Diameter: 150 mm – 900 mm

-

Thickness: 10 mm – 50 mm

-

Bore size: 31.8 mm / 76.2 mm / 127mm / 203.2 mm / 304.8 mmCustom

-

Grit size: 24# – 120#

-

Bond: Vitrified (V)

-

Hardness: Soft to Hard (K–P)

In addition, custom formulations are available according to machine type and grinding requirements.

Key Advantages of Our Vitrified Grinding Wheels

-

Stable structure and excellent shape retention

-

High grinding accuracy and consistent performance

-

Good heat dissipation and thermal stability

-

Long service life and reduced wheel consumption

-

Suitable for heavy-duty and precision grinding

As a result, users benefit from higher productivity and lower overall grinding costs.

Why Choose Us as Your Vitrified Grinding Wheel Manufacturer

With years of manufacturing and export experience, we understand the grinding requirements of different industries.

Therefore, we provide not only reliable grinding wheels but also technical support and application recommendations to help customers select the right solution.

Call to Action

Looking for a reliable vitrified grinding wheel manufacturer?

Contact us today to get technical support, pricing, and customized grinding wheel solutions for your application.