Grinding Wheel vs CBN Wheel: Which Is Better for Crankshafts?

Crankshaft grinding demands high accuracy, stable cutting performance, and strict dimensional control. As a result, selecting the right grinding wheel directly affects surface quality, cycle time, and overall production cost.

Among the most common choices, conventional grinding wheels and CBN wheels serve different purposes. Therefore, understanding their differences helps workshops and manufacturers make better decisions for crankshaft grinding applications.

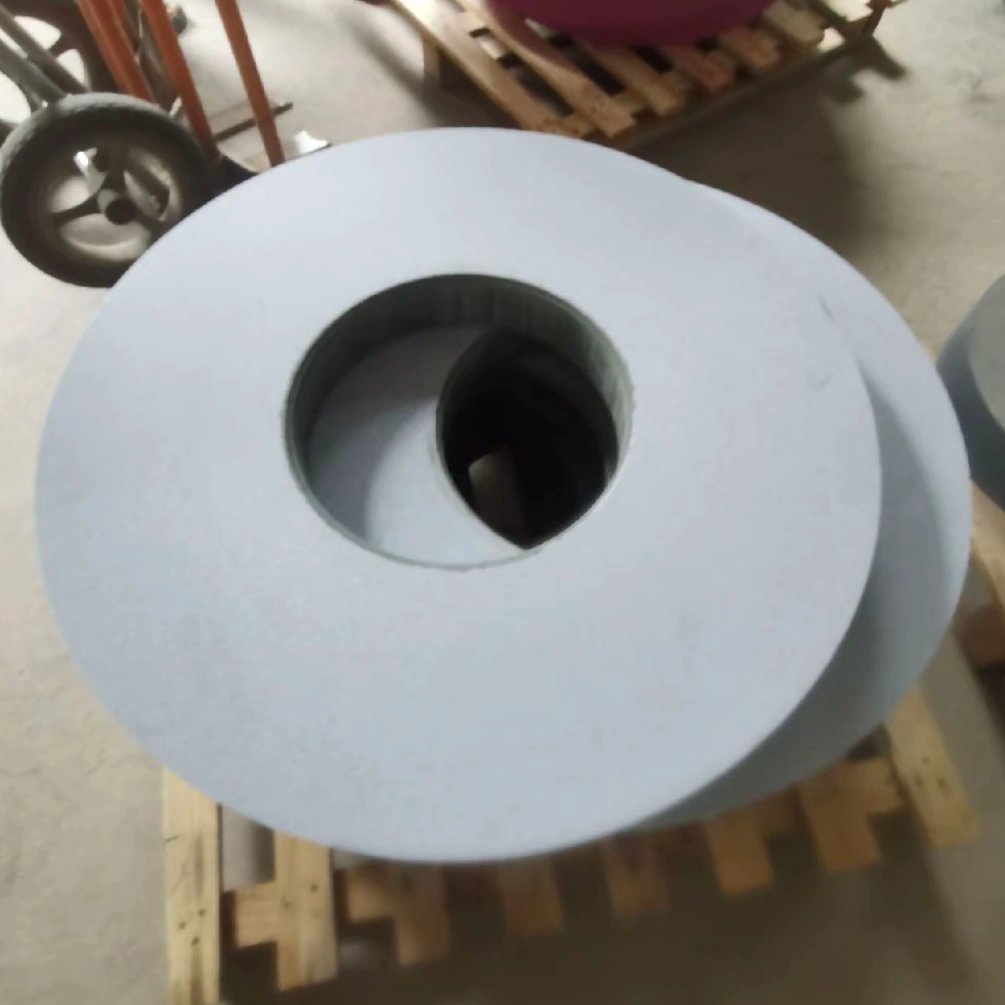

Understanding Conventional Grinding Wheels for Crankshafts

Conventional grinding wheels typically use aluminum oxide or silicon carbide abrasives bonded with vitrified or resin systems. Manufacturers widely apply these wheels in crankshaft grinding because they offer flexibility, easy dressing, and lower initial cost.

Moreover, crankshaft grinding wheels made with vitrified bonds provide good form retention and stable grinding behavior. As a result, they remain a practical solution for small to medium production volumes and engine repair workshops.

However, conventional wheels wear faster and require more frequent dressing. Consequently, operators must balance wheel life and productivity.

What Makes CBN Wheels Different?

CBN (Cubic Boron Nitride) wheels use superabrasive grains that deliver extremely high hardness and thermal stability. Therefore, they perform exceptionally well in high-speed and high-volume crankshaft grinding.

CBN wheels maintain sharp cutting edges over long production runs. As a result, they reduce dressing frequency and maintain consistent profile accuracy. In addition, they generate less heat, which improves surface integrity and reduces the risk of burns.

However, CBN wheels require higher initial investment and more precise machine conditions. Therefore, they are typically used in high-output production lines rather than general repair shops.

Key Performance Comparison

Grinding Efficiency

CBN wheels remove material faster and maintain cutting efficiency longer. In contrast, conventional grinding wheels provide more flexible control but require frequent maintenance.

Wheel Life

CBN wheels significantly outperform conventional wheels in service life. Consequently, they reduce downtime caused by wheel changes and dressing.

Accuracy and Surface Finish

Both wheel types can achieve high accuracy. However, vitrified grinding wheels allow easier profile correction during dressing, which benefits complex crankshaft geometries.

Cost Consideration

Conventional grinding wheels offer lower upfront cost. Meanwhile, CBN wheels reduce cost per part in high-volume production through extended life and reduced downtime.

Which Wheel Is Better for Crankshaft Grinding?

The answer depends on application conditions.

For engine repair shops, remanufacturing facilities, and flexible production environments, conventional grinding wheels remain a cost-effective and adaptable choice. They allow frequent dressing and quick adjustment for different crankshaft types.

On the other hand, large-scale manufacturers focused on high throughput and automation benefit more from CBN wheels. In these cases, long wheel life and stable performance outweigh higher initial cost.

Therefore, buyers should evaluate production volume, machine capability, and total grinding cost rather than focusing solely on wheel price.

Practical Selection Tips

When selecting a wheel for crankshaft grinding, consider the following:

- Production volume and cycle time requirements

- Machine rigidity and spindle power

- Dressing capability and operator skill

- Target surface finish and tolerance

By matching the wheel type to actual production needs, users achieve optimal performance and cost efficiency with industrial grinding wheels designed for crankshaft applications.

Conclusion

Both conventional grinding wheels and CBN wheels play important roles in crankshaft grinding. Conventional wheels offer flexibility and cost control, while CBN wheels deliver unmatched efficiency and longevity in high-volume environments.

Ultimately, the better choice depends on your production goals, equipment, and long-term cost strategy.