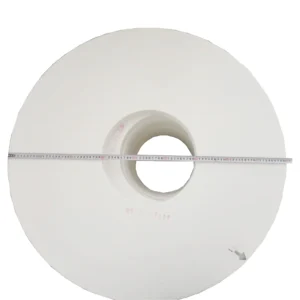

Vitrified Grinding Wheel Manufacturer & Supplier for Industrial Applications

HTF Materials is a professional vitrified grinding wheels manufacturer and supplier, providing high-performance grinding solutions for precision machining and heavy-duty industrial applications. Our vitrified bond grinding wheels are engineered to deliver excellent cutting efficiency, dimensional accuracy, and long service life across a wide range of materials.

With stable quality control and customized manufacturing capability, we support global customers in metal fabrication, automotive, tooling, and industrial grinding industries.

What Are Vitrified Grinding Wheels?

Vitrified grinding wheels are bonded with a ceramic (vitrified) bond that offers high rigidity, excellent thermal resistance, and strong grain retention. Compared with resin-bond wheels, vitrified bond grinding wheels maintain better shape accuracy and perform consistently under high-speed and high-load grinding conditions.

Thanks to their porous structure, vitrified grinding wheels provide effective chip clearance and coolant penetration, helping reduce grinding burns and improve surface finish.

Key Features of Vitrified Grinding Wheel

- High structural rigidity for precise grinding

- Excellent heat resistance for stable performance

- Strong grain holding force and controlled wear

- Consistent cutting ability and long wheel life

- Suitable for both wet and dry grinding applications

Our vitrified grinding wheel is designed to meet the demanding requirements of industrial and CNC grinding operations.

Applications

HTF Materials’ vitrified grinding wheels are widely used in:

- Crankshaft and camshaft grinding

- Surface grinding

- Cylindrical and internal grinding

- Tool and cutter grinding

- CNC grinding machines

- Roll grinding and heavy-duty machining

They are suitable for grinding carbon steel, alloy steel, hardened steel, and other engineering materials.

Available Sizes, Grits & Specifications

We supply vitrified grinding wheel in a wide range of specifications, including:

- Wheel diameter: Ø150 – Ø1250 mm

- Bore size: Customized according to machine requirements

- Thickness: Customized

- Grit size: Coarse to fine (e.g. 24# – 220#)

- Abrasives: Aluminum oxide, silicon carbide, and customized formulations

Custom vitrified bond formulations are available based on your grinding process and workpiece material.

Why Choose HTF Materials

- Experienced manufacturer focused on industrial grinding solutions

- Stable quality and strict inspection standards

- Custom wheel design for specific applications

- Competitive pricing for B2B orders

- Reliable export experience and global supply capability

We work closely with customers to ensure our vitrified grinding wheels match their machines, materials, and production requirements.

Request a Quote

If you are looking for a reliable vitrified grinding wheels supplier, HTF Materials is ready to support your project.

Please contact us with your application details, material, and wheel size requirements, and our technical team will provide a suitable solution.