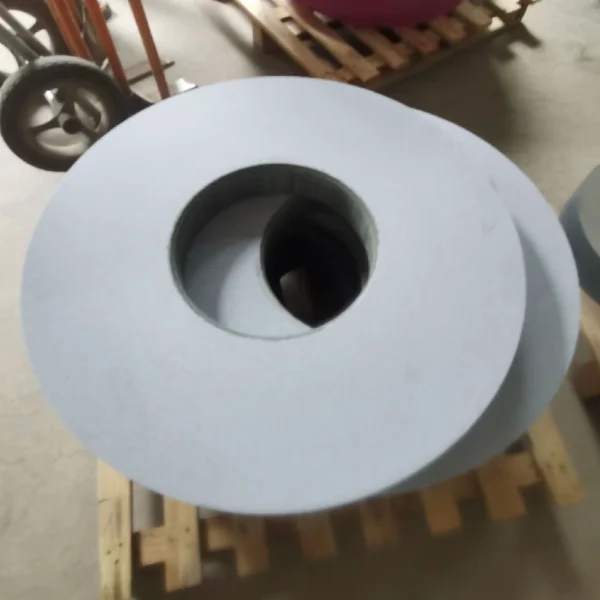

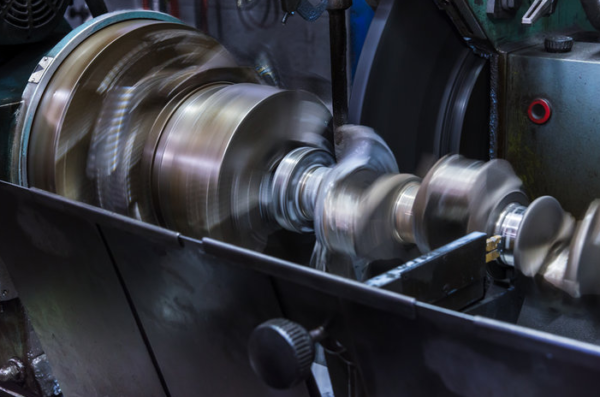

Roll Grinding Wheel: Complete Guide for Steel & Paper Industry

Roll Grinding Wheel: Complete Guide for Steel & Paper Industry A roll grinding wheel plays a critical role in maintaining the precision and surface quality of industrial rolls. Steel mills, paper mills, and aluminum plants rely on high-performance roll grinding wheels to ensure consistent production quality. Therefore, choosing the correct roll grinding wheel directly impacts […]

Roll Grinding Wheel: Complete Guide for Steel & Paper Industry Read More »