Which Grinding Wheel Is Used for Stainless Steel Grinding?

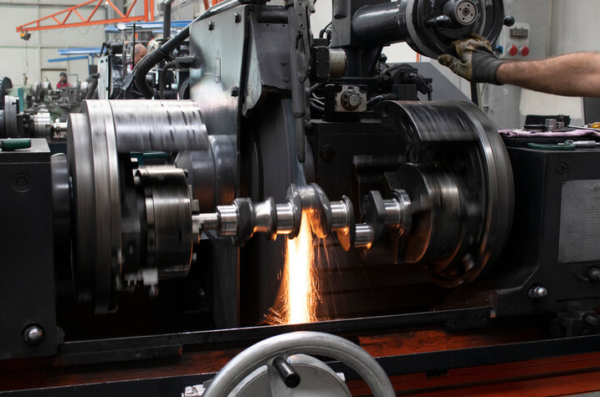

Which Grinding Wheel Is Used for Stainless Steel Grinding? Grinding stainless steel requires the right grinding wheel selection. Because stainless steel is tough, ductile, and heat-sensitive, using the wrong wheel can quickly cause burning, glazing, poor surface finish, or excessive wheel wear. Therefore, choosing a suitable grinding wheel is critical for efficiency and surface quality. […]

Which Grinding Wheel Is Used for Stainless Steel Grinding? Read More »