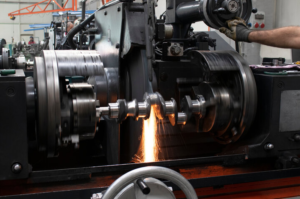

What Is a Crankshaft Grinding Wheel?

A crankshaft grinding wheel is a vitrified bonded grinding wheel specifically designed for grinding crankshaft journals, main journals, and crankpins.

Because crankshafts are usually made from medium carbon steel or alloy steel and often heat-treated, the grinding process requires high sharpness, thermal stability, and dimensional accuracy.

Therefore, selecting the right grinding wheel is essential for achieving consistent surface finish, avoiding burns, and extending crankshaft service life.

Common Types of Crankshaft Grinding Wheels

1. White Aluminum Oxide Crankshaft Grinding Wheel (WA)

White aluminum oxide grinding wheels are widely used for precision crankshaft grinding.

Key advantages:

- Excellent self-sharpening ability

- Low grinding heat, reducing the risk of burns

- Stable cutting performance for fine grinding

Typical applications:

- Automotive engine crankshafts

- Marine diesel engine crankshafts

- Precision crankshaft regrinding workshops

2. Brown Aluminum Oxide / Pink Aluminum Oxide Crankshaft Grinding Wheel (A / PA)

Besides, brown aluminum oxide wheels also offer higher toughness and longer service life, making them suitable for heavier grinding conditions.

Key advantages:

- Strong impact resistance

- Longer wheel life

- Ideal for rough grinding and high stock removal

Typical applications:

- Large crankshaft rough grinding

- Heavy-duty engine crankshafts

- Industrial repair workshops

3. Vitrified Bond Crankshaft Grinding Wheel

Most professional crankshaft grinding wheels use vitrified bond because it provides excellent balance between strength and porosity.

Why vitrified bond matters:

- Good porosity improves coolant penetration

- Easy dressing maintains wheel profile

- High dimensional stability during grinding

As a result, vitrified crankshaft grinding wheels are ideal for high-precision and continuous grinding operations.

Key Parameters When Selecting a Crankshaft Grinding Wheel

Choosing the right specifications directly affects grinding efficiency and surface quality.

🔹 Grit

- Rough grinding: 36# / 46#

- Semi-finishing: 54# / 60#

- Finishing: 80# or finer

🔹 Wheel Hardness

- Medium-soft to medium grades (J–M)

- Helps maintain sharp cutting edges and prevents thermal damage

🔹 Wheel Size

- Common diameters: 600 mm / 700 mm / 750 mm / 900mm / 915mm

- Bore size and thickness customized according to grinding machine requirements

Applications of Crankshaft Grinding Wheels

Crankshaft grinding wheels are widely used across multiple industries, for example:

- Automotive engine manufacturing and repair

- Marine diesel engine maintenance

- Construction and heavy machinery

- Power generation equipment

- Professional crankshaft reconditioning workshops

Therefore, both single-piece repair and batch production rely heavily on stable and high-performance grinding wheels.

How to Improve Crankshaft Grinding Performance

To achieve optimal grinding results, manufacturers and workshops should:

- Select the correct abrasive and grit size combination

- Dress the grinding wheel regularly

- Apply sufficient coolant to control grinding temperature

- Optimize wheel speed and feed rate based on crankshaft material

Moreover, a properly matched grinding wheel can increase efficiency by more than 20% while improving surface finish consistency.

The Right Crankshaft Grinding Wheel Makes the Difference

In summary, crankshaft grinding is a high-precision process that demands reliable and consistent grinding wheels.

By choosing the right abrasive, grit, bond, and grinding wheel specification, you can significantly improve grinding accuracy, reduce downtime, and extend wheel life.

If you are looking for custom crankshaft grinding wheels or professional technical support, feel free to contact us for tailored solutions.