In modern engine manufacturing, precision machining plays a critical role in ensuring performance, durability, and efficiency. As a result, grinding wheels have become essential tools for achieving tight tolerances, smooth surface finishes, and consistent dimensional accuracy across key engine components.

This article explores the role of grinding wheels in engine manufacturing, common applications, recommended abrasive types, and how to choose the right grinding wheel for optimal results.

Why Grinding Wheels Are Essential in Engine Manufacturing

Engine components operate under high temperature, high pressure, and high-speed conditions. Therefore, manufacturers must rely on grinding processes to achieve superior accuracy and surface integrity that conventional machining alone cannot provide.

Grinding wheels enable:

- Precise material removal

- Excellent surface finish

- Controlled heat generation

- High repeatability in mass production

Consequently, they are widely used in both automotive and industrial engine production.

Key Engine Components That Require Grinding

Grinding wheels are commonly used in the manufacturing of critical engine parts, including:

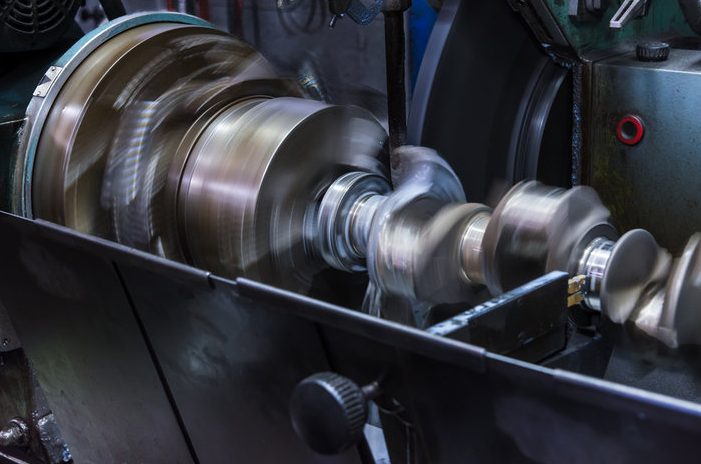

• Crankshafts

Crankshaft grinding requires high rigidity and stable cutting performance. Vitrified-bond grinding wheels are often preferred for their precision and dimensional stability.

• Camshafts

Camshaft lobes demand accurate profiles and smooth surfaces. As a result, specially formulated grinding wheels help maintain profile accuracy while reducing burn marks.

• Cylinder Heads and Engine Valves

Valve grinding and seat grinding require fine surface finishes to ensure proper sealing. Therefore, fine-grit grinding wheels are widely used in this process.

• Engine Blocks and Bearing Surfaces

Surface grinding ensures flatness and consistency. Moreover, controlled grinding reduces vibration and noise during engine operation.

Recommended Grinding Wheel Types for Engine Manufacturing

Different engine components require different abrasive solutions. Accordingly, the following grinding wheels are commonly used:

- White Aluminum Oxide Grinding Wheels

Ideal for alloy steel and hardened steel components such as crankshafts and camshafts. - Green Silicon Carbide Grinding Wheels

Suitable for non-ferrous materials, carbide tools, and precision finishing applications. - Brown Aluminum Oxide Grinding Wheels

Suitable for general-purpose engine components, forged steel, and carbon steel parts. Moreover, they provide strong toughness, stable grinding behavior, and cost-effective performance. - Pink Aluminum Oxide Grinding Wheels

Ideal for high-load and heavy-duty grinding applications. As a result, they deliver improved wear resistance, longer wheel life, and enhanced thermal stability when grinding critical engine parts.

Benefits of Using the Right Grinding Wheel

When properly selected, grinding wheels can significantly improve engine manufacturing efficiency:

- Improved dimensional accuracy

- Reduced grinding burns and thermal damage

- Longer wheel life and fewer dressing cycles

- Higher productivity and lower production costs

As a result, manufacturers achieve more consistent quality and reduced downtime.

How to Choose the Right Grinding Wheel for Engine Manufacturing

To select the optimal grinding wheel, manufacturers should consider:

- Material type (forged steel, cast iron, alloy steel)

- Required surface roughness

- Machine speed and rigidity

- Production volume and cycle time

Ultimately, working with an experienced grinding wheel manufacturer ensures that the wheel specification matches both the application and the production environment.

Conclusion

In conclusion, grinding wheels play a vital role in engine manufacturing by delivering the precision, surface quality, and reliability required for critical engine components. With the right abrasive selection and customized specifications, manufacturers can enhance productivity, ensure consistent quality, and meet the increasing demands of modern engine production.