Introduction

Marine engines operate under extreme conditions, including high loads, continuous operation, and corrosive environments. As a result, precision grinding becomes essential during marine engine repair and overhaul.

Choosing the right grinding wheel directly affects machining accuracy, surface finish, and component lifespan.

Therefore, understanding how to select grinding wheels for marine engine repair helps workshops improve efficiency while reducing rework and downtime.

Common Marine Engine Components That Require Grinding

In marine repair workshops, grinding operations usually focus on the following components:

- Crankshafts

- Propeller shafts

- Intermediate shafts

- Camshafts

- Bearing journals

Each component requires different grinding wheel specifications, depending on material hardness, grinding method, and required surface finish.

Step 1: Choose the Right Abrasive Material

The abrasive material is the core of grinding wheel performance.

Aluminum Oxide (A) is the most widely used abrasive for marine engine repair. It is suitable for:

- Carbon steel

- Alloy steel

- Forged crankshafts

- Large marine shafts

Because aluminum oxide offers good toughness and self-sharpening ability, it performs well in both rough and finish grinding.

In contrast, silicon carbide wheels are generally not recommended for steel crankshafts, as they wear too quickly under heavy loads.

Step 2: Select the Proper Grit Size

Grit size determines cutting speed and surface finish.

- Coarse grit (36–46)

Used for rough grinding, material removal, and crankshaft reconditioning. - Medium grit (60–80)

Ideal for semi-finishing and general shaft grinding. - Fine grit (100 and above)

Applied when a smoother surface finish is required.

For marine engine repair, 60 or 80 grit is the most common choice, as it balances efficiency and surface quality.

Step 3: Understand Wheel Hardness (Grade)

Grinding wheel grade refers to how strongly the bond holds the abrasive grains.

- Soft grades (K–L)

Suitable for hard materials such as hardened crankshafts. - Medium grades (M–N)

Commonly used for general marine shaft grinding.

If the wheel is too hard, it may burn the workpiece.

If it is too soft, wheel wear increases.

Selecting the correct grade ensures stable grinding and consistent results.

Step 4: Choose the Bond Type

For marine engine repair, vitrified bond grinding wheels (V) are the preferred option.

They offer:

- High dimensional accuracy

- Good heat resistance

- Stable grinding performance

- Easy dressing

Vitrified grinding wheels are widely used in crankshaft grinding machines and large cylindrical grinders found in marine workshops.

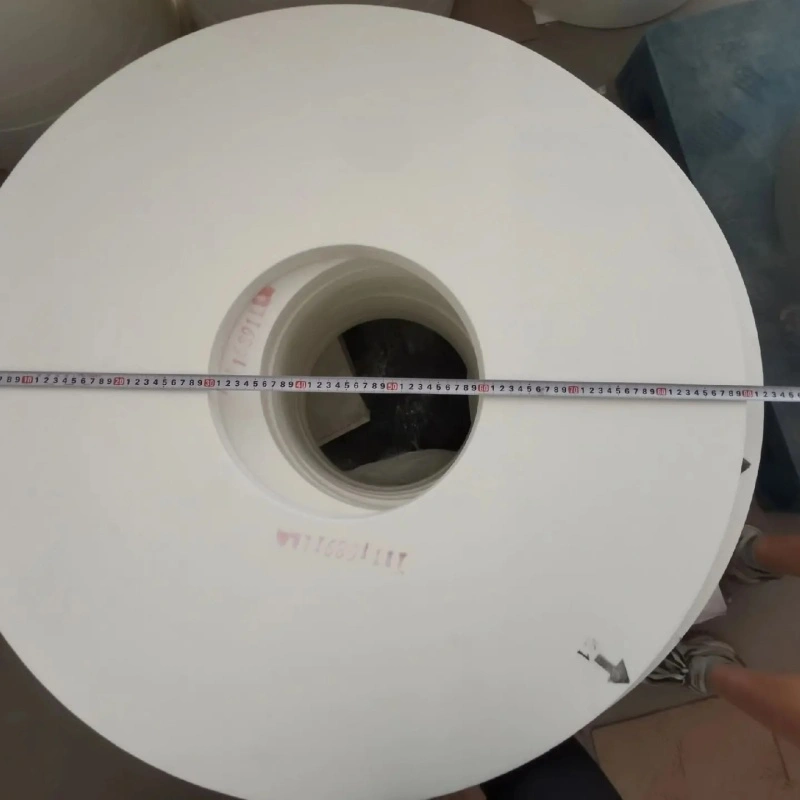

Step 5: Confirm Common Grinding Wheel Sizes

Marine engine components are usually large, so grinding wheels must match machine capacity.

Typical sizes for marine crankshaft and shaft grinding include:

- Diameter: 600 mm / 750 mm / 800 mm / 900 mm

- Thickness: 16 mm / 18 mm / 22 mm

- Bore: 203.2 mm / 304.8 mm

Choosing the correct size ensures safe operation and proper grinding pressure distribution.

Common Grinding Wheel Specification Example

A typical specification for marine crankshaft grinding:

A 60 L 5 V

- Abrasive: Aluminum Oxide

- Grit: 60

- Grade: L

- Structure: 5

- Bond: Vitrified

This type of grinding wheel is widely used in ship repair yards and marine engine overhaul centers.

Why the Right Grinding Wheel Matters

Using the correct grinding wheel helps you:

- Improve grinding accuracy

- Reduce thermal damage

- Extend crankshaft service life

- Lower wheel consumption

- Increase workshop productivity

In marine engine repair, reliability is critical. A properly selected grinding wheel ensures consistent performance under demanding conditions.

Final Thoughts

Selecting grinding wheels for marine engine repair is not just about size or price. Instead, it requires careful consideration of abrasive type, grit size, grade, bond, and application.

By choosing the right vitrified grinding wheel, marine repair workshops can achieve higher precision, longer component life, and more efficient operations.

If you are sourcing grinding wheels for marine crankshaft or shaft repair, selecting a supplier with experience in heavy-duty applications is equally important.