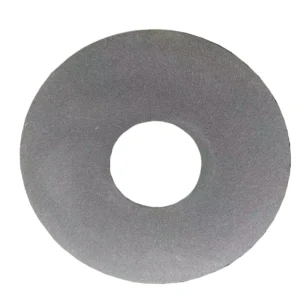

What Is a Camshaft Grinding Wheel?

A camshaft grinding wheel is a specialized grinding wheel used for precision grinding of camshaft profiles, including cam lobes and journals. Due to the complex geometry of camshafts, these grinding wheels require high form stability and consistent abrasive performance.

It is widely used in automotive engines, marine engines, diesel generators, and heavy machinery repair workshops, making it an ideal choice for both OEM production and crankshaft regrinding applications.

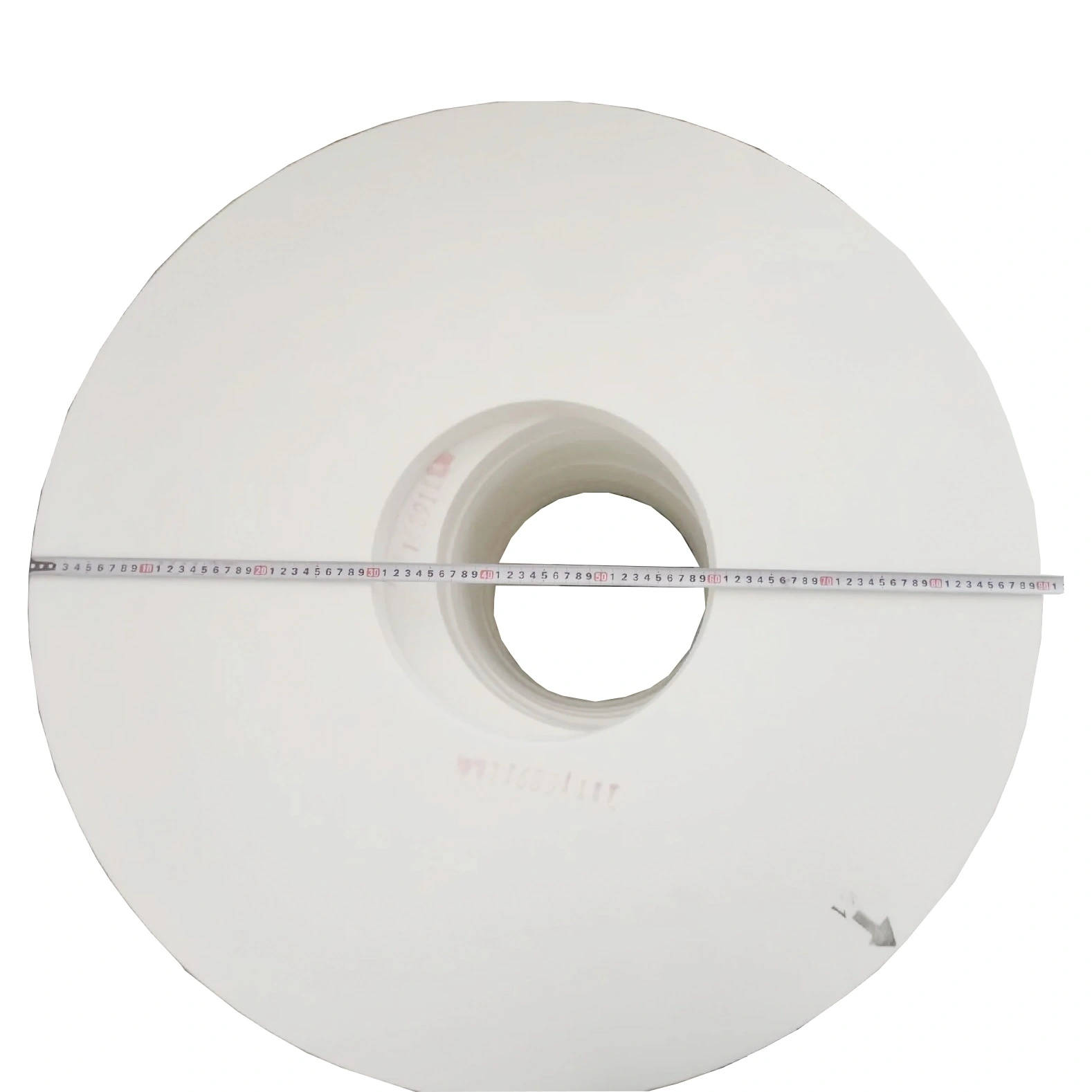

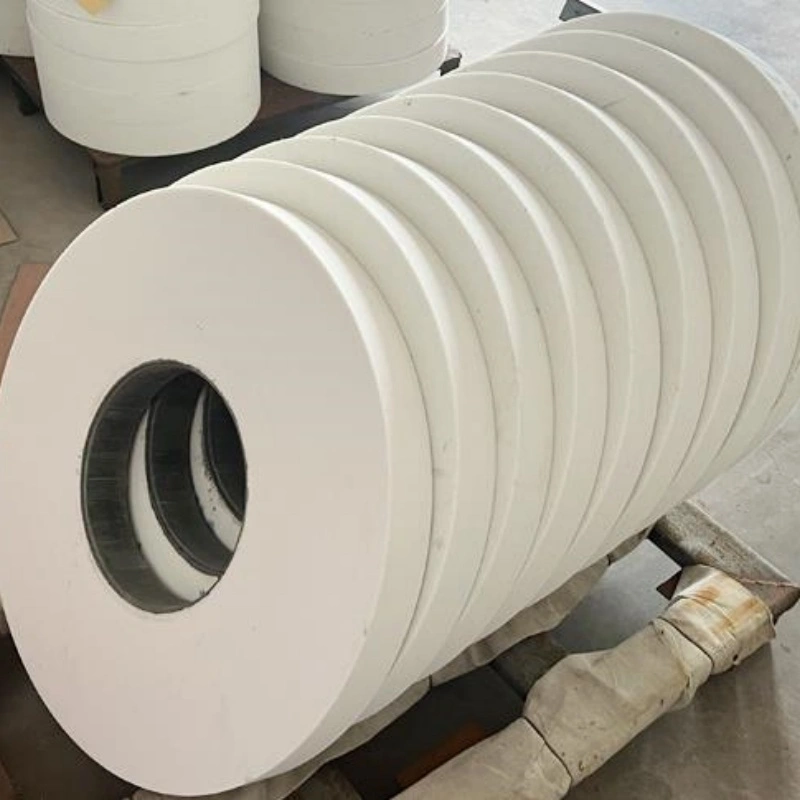

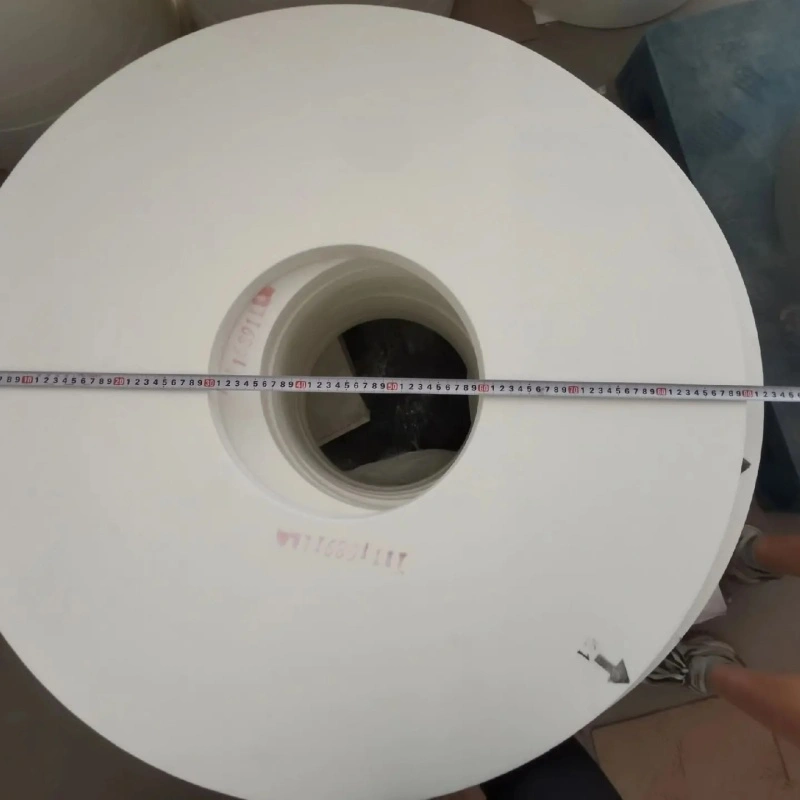

Specifications

- Ø700 * 18 * 203.2mm

- Ø800 * 20 * 304.8mm

- Ø900 * 20 * 304.8mm

- Ø915 * 25 * 304.8mm

- Ø1100 * 25 * 304.8mm

- Ø1250 * 50* 304.8mm

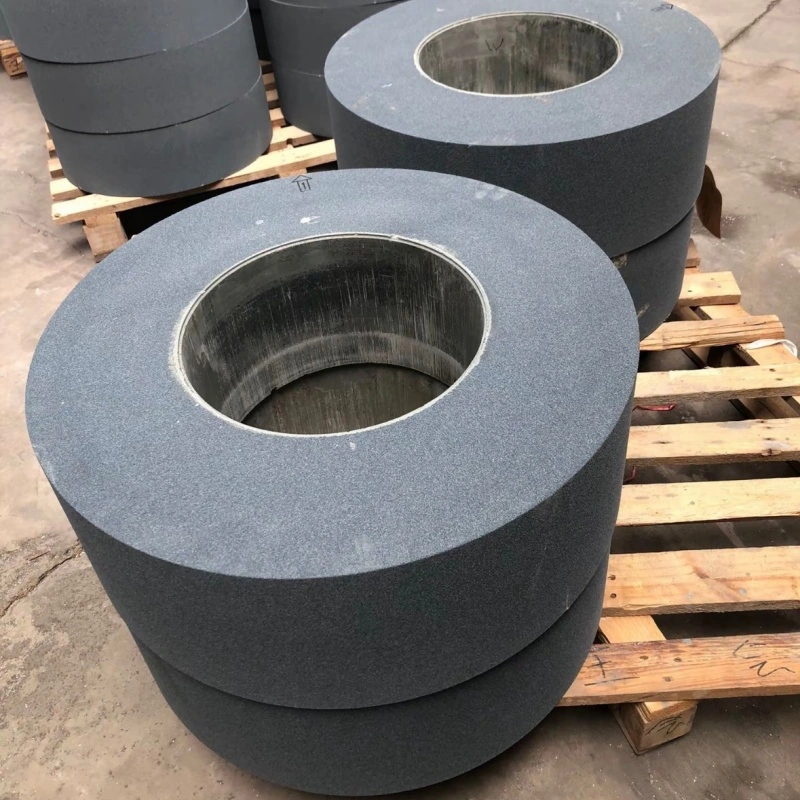

Bond Types:

• Vitrified bond (recommended)

• Resin bond

Abrasives:

• White Aluminum Oxide (WA)

• Aluminum Oxide

• Custom abrasive solutions available

Grit: 36 / 46 / 60 / 80

Hardness: Medium to Hard

Custom sizes available upon request

We also supply grinding wheels for repair workshops with custom sizes and specifications.

Applications

• Automotive camshaft grinding

• Diesel engine camshaft repair

• Engine remanufacturing

• CNC camshaft grinding machines

• Performance engine workshops

For repair workshops, a vitrified bond grinding wheel ensures stable grinding performance and long service life.

Key Features of Our Camshaft Grinding Wheels

- High profile accuracy for cam lobes

- Excellent form retention

- Stable cutting action

- Controlled heat generation

- Long service life

FAQ – Camshaft Grinding Wheel

1. Which grinding wheel do you use for camshaft grinding?

You typically use vitrified bonded grinding wheels for camshaft grinding because they maintain profile accuracy, provide stable cutting action, and ensure consistent surface finish during high-precision grinding.

2. Which abrasive works best for camshaft grinding?

You should choose the abrasive according to camshaft material:

White Aluminum Oxide (WA/A) works best for alloy steel and hardened steel camshafts

Green Silicon Carbide (GC) suits cast iron camshafts

Selecting the correct abrasive improves grinding efficiency and wheel life.

3. What grit size should you select for camshaft grinding wheels?

You commonly select:

46–60 grit for rough and semi-finish grinding

80 grit for finish grinding when you require fine surface quality and profile accuracy

Your final selection depends on cam lobe hardness and surface finish requirements.

4. What sizes do the camshaft grinding wheels come in?

Manufacturers commonly supply camshaft grinding wheels in outer diameters such as Ø400, Ø500, Ø600, Ø750, and Ø800 mm.

You can customize wheel thickness and bore size to fit different camshaft grinding machines.

5. What causes grinding burn or profile errors during camshaft grinding?

Grinding burn or profile errors occur when you use an incorrect wheel specification, apply excessive grinding pressure, supply insufficient coolant, or dress the wheel improperly.

You can reduce these issues by selecting the correct grit size, vitrified bond, and dressing method.