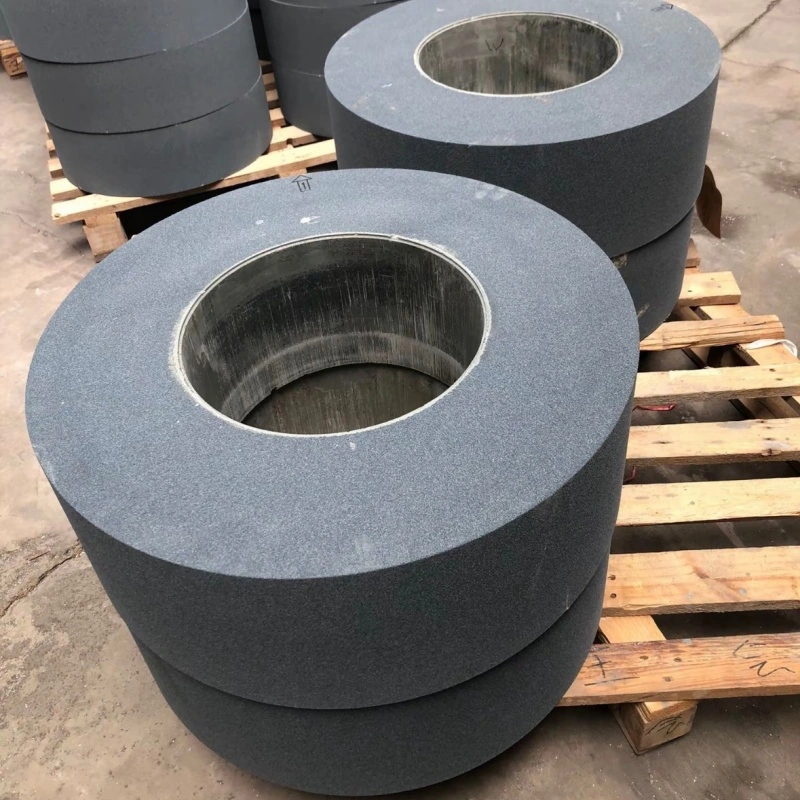

Cylindrical Grinding Wheel

Cylindrical Grinding Wheels for Precision Industrial Applications

HTF Materials supplies high-performance cylindrical grinding wheels designed for precision grinding of cylindrical components in automotive, mechanical, and heavy industrial applications. Our grinding wheels deliver stable cutting performance, excellent form retention, and consistent surface finish, making them ideal for both OD (outside diameter) and ID (inside diameter) grinding operations.

As an experienced grinding wheel manufacturer, we provide customized cylindrical grinding wheel solutions to meet different materials, machine types, and production requirements.

What Is a Cylindrical Grinding Wheel?

A cylindrical grinding wheel is a type of abrasive wheel specifically used for cylindrical grinding processes, where the workpiece is rotated while being ground to achieve high dimensional accuracy and superior surface quality. Cylindrical grinding wheels are commonly used for shafts, rods, bearings, and other round components that require tight tolerances.

Compared with general-purpose grinding wheels, cylindrical grinding wheels require higher precision, better balance, and stable abrasive performance to ensure consistent results during continuous grinding operations.

Key Features of Our Cylindrical Grinding Wheels

Our cylindrical grinding wheels are engineered to meet demanding industrial requirements and deliver reliable grinding performance.

- High form retention

Maintains wheel shape during long grinding cycles, ensuring consistent accuracy. - Stable cutting performance

Uniform abrasive distribution provides smooth and efficient material removal. - Excellent thermal stability

Vitrified bond structure allows effective heat dissipation, reducing thermal damage to workpieces. - Consistent surface finish

Produces controlled surface roughness suitable for precision machining. - Long service life

Optimized bond and abrasive selection extend wheel lifespan and reduce replacement frequency.

Applications of Cylindrical Grinding Wheels

HTF Materials cylindrical grinding wheels are widely used in various industries and grinding processes, including:

- Outside Diameter (OD) grinding

- Inside Diameter (ID) grinding

- Automotive shaft grinding

- Crankshaft and camshaft components

- Bearing and sleeve grinding

- Hydraulic and mechanical parts

- CNC cylindrical grinding machines

- Engine repair and remanufacturing workshops

These grinding wheels are suitable for both mass production and repair applications, delivering reliable performance in diverse working environments.

Available Materials and Bond Types

To meet different grinding requirements, we offer cylindrical grinding wheels in various material and bond configurations.

Abrasive Materials

- Aluminum Oxide (A)

- White Aluminum Oxide (WA)

- Brown Aluminum Oxide

- Silicon Carbide (GC)

Bond Types

- Vitrified bond (recommended for precision cylindrical grinding)

- Resin bond

- Custom bond solutions upon request

The vitrified bond structure provides excellent rigidity, heat resistance, and dimensional stability, making it the preferred choice for high-precision cylindrical grinding applications.

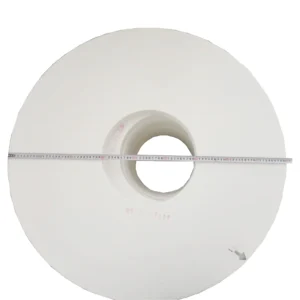

Sizes and Specifications

We supply cylindrical grinding wheels in a wide range of sizes and specifications to match different grinding machines and applications.

Typical Specifications:

- Diameter: Ø150 – Ø900 mm

- Width: Customized

- Bore size: Customized

- Grit size: 36 / 46 / 60 / 80 / 120 / 180 / 240

- Hardness: Medium to Hard

- Structure: Open / Medium / Dense

Custom sizes and specifications are available based on your machine model, workpiece material, and grinding conditions.

Cylindrical Grinding Wheel for OD and ID Grinding

Our cylindrical grinding wheels are designed to perform effectively in both OD and ID grinding processes.

-

OD Grinding:

Ideal for grinding external surfaces of shafts and cylindrical components with high dimensional accuracy. -

ID Grinding:

Suitable for internal grinding operations requiring precision and smooth surface finishes.

The optimized abrasive structure ensures efficient material removal while maintaining excellent surface quality in both grinding modes.

How to Choose the Right Cylindrical Grinding Wheel

Selecting the correct cylindrical grinding wheel is essential for achieving optimal grinding results. Key factors to consider include:

- Workpiece material (steel, alloy steel, hardened steel, etc.)

- Grinding machine type (manual or CNC)

- Required surface finish and tolerance

- Grinding speed and feed rate

- Cooling and dressing conditions

Our technical team can assist you in selecting the most suitable cylindrical grinding wheel based on your specific application requirements.

Dressing and Maintenance

Proper dressing is essential to maintain the cutting performance and accuracy of cylindrical grinding wheels. Regular dressing helps:

- Restore wheel sharpness

- Maintain correct wheel profile

- Improve surface finish consistency

- Extend wheel service life

We provide technical guidance on dressing methods and parameters to ensure stable grinding performance throughout the wheel’s lifespan.

Why Choose HTF Materials as Your Grinding Wheel Supplier

HTF Materials is committed to delivering reliable grinding wheel solutions for global industrial customers.

- Professional grinding wheel manufacturer

- Stable and consistent product quality

- Custom solutions for specific applications

- Strict quality control standards

- Export experience serving international B2B customers

- Technical support for wheel selection and application

Our cylindrical grinding wheels are trusted by customers in automotive, machinery manufacturing, and industrial maintenance sectors worldwide.

Quality Control and Manufacturing Process

Each cylindrical grinding wheel is manufactured under strict quality control procedures, including raw material inspection, bonding control, balance testing, and performance evaluation. This ensures every wheel meets industrial standards and delivers consistent grinding results.

Contact Us for Cylindrical Grinding Wheel Solutions

If you are looking for reliable cylindrical grinding wheels for precision grinding applications, HTF Materials is ready to support your needs. We offer customized solutions based on your machine type, workpiece material, and production requirements.

Contact us today to discuss your application or request a quotation.

Related Grinding Wheel Solutions

- Industrial Grinding Wheels

- Vitrified Bond Grinding Wheels

- Crankshaft Grinding Wheels

- Surface Grinding Wheels