Grinding Wheel for Repair Workshop

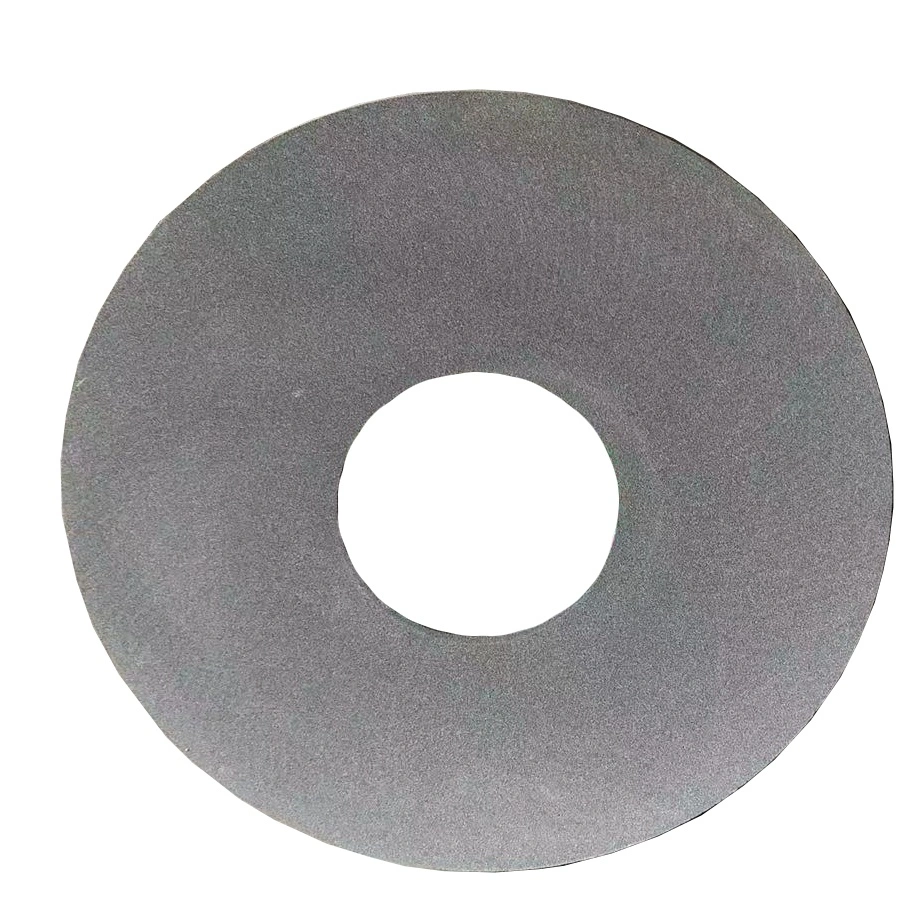

Product Description

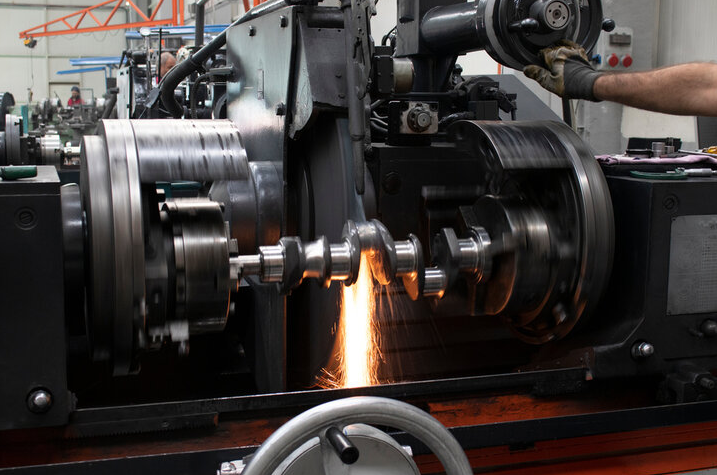

This grinding wheel for repair workshop is engineered to handle a wide range of grinding tasks, including shaft grinding, crankshaft reconditioning, and cylindrical grinding.

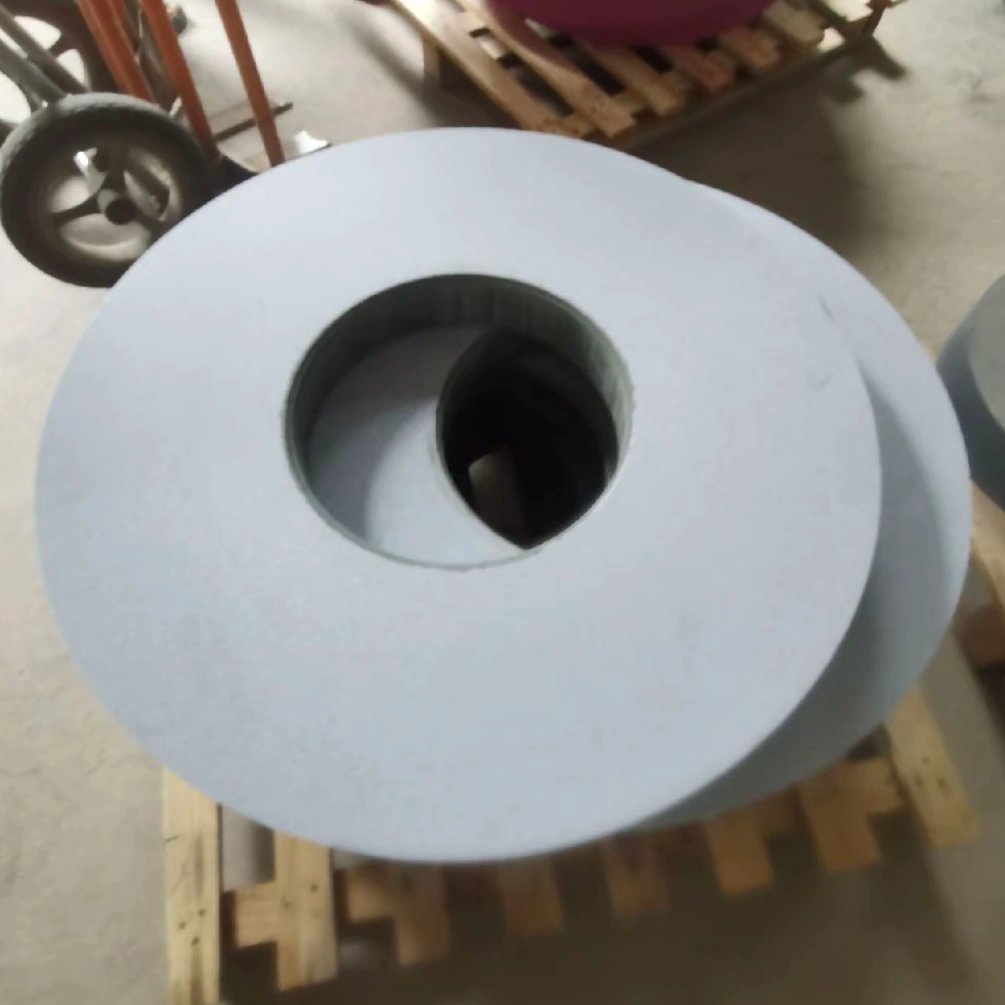

Moreover, its balanced structure ensures smooth operation, which helps reduce vibration and improve surface finish.

In addition, the grinding wheel provides consistent cutting action and controlled wear. As a result, operators can maintain dimensional accuracy while extending wheel life.

Because repair workshops often work on different materials and job types, this grinding wheel offers excellent versatility and easy operation.

Furthermore, the wheel performs reliably on carbon steel, alloy steel, and cast iron, making it suitable for both rough grinding and finishing processes.

Typical Applications in Repair Workshops

This grinding wheel is widely used in various repair and maintenance environments, such as:

- Engine repair and overhaul workshops

- Crankshaft and shaft repair facilities

- Marine engine maintenance workshops

- General machinery repair shops

- Automotive service and reconditioning centers

Therefore, it is an ideal solution for workshops requiring stable and cost-effective grinding performance.

Available Specifications

To meet different machine and workshop requirements, we offer multiple specifications:

- Shape: Type 1

- Diameter: Ø500 – Ø900 mm

- Thickness: 16 mm – 40 mm

- Bore size: 203.2 mm / 304.8 mm / Custom

- Abrasive: A/ WA/ PA/ SG/

- Grit size: 36# / 46# / 60# / 80# / 100#

- Hardness: Medium to hard, suitable for workshop use

- Bond type: Vitrified (V)

In addition, customized grinding wheels are available upon request.

Key Benefits for Repair Workshops

- Stable grinding performance under frequent operation

- Smooth cutting action with reduced vibration

- Suitable for multiple repair applications

- Long service life and cost-effective usage

- Easy to dress and maintain

As a result, repair workshops can improve efficiency while reducing grinding wheel consumption.

Related Grinding Solutions

As part of our grinding solutions, we also supply:

- Vitrified grinding wheels for crankshaft grinding

- Shaft grinding wheels for repair and maintenance

- Cylindrical grinding wheels for general machining

These products help repair workshops handle different grinding tasks with consistent results.

Why Choose Our Grinding Wheel for Repair Workshop

With extensive experience in supplying grinding wheels for repair workshops worldwide, we understand the practical needs of maintenance and reconditioning operations.

Therefore, we provide reliable products along with technical support to help customers select the most suitable grinding wheel.

Packaging & Shipping

Our grinding wheel for repair workshop is carefully packed to ensure safe transportation and storage.

Therefore, we use strong carton packaging combined with pallets, which effectively protects the grinding wheels from damage during handling and long-distance shipping.

Each grinding wheel is securely packed inside a durable carton. In addition, cartons are placed on solid pallets and properly fixed to prevent movement during transport.

As a result, the grinding wheels arrive in good condition and are ready for immediate use upon delivery.

Call to Action

Looking for a reliable grinding wheel for repair workshop?

Contact us today to get technical recommendations, pricing, and customized grinding wheel solutions for your repair applications.