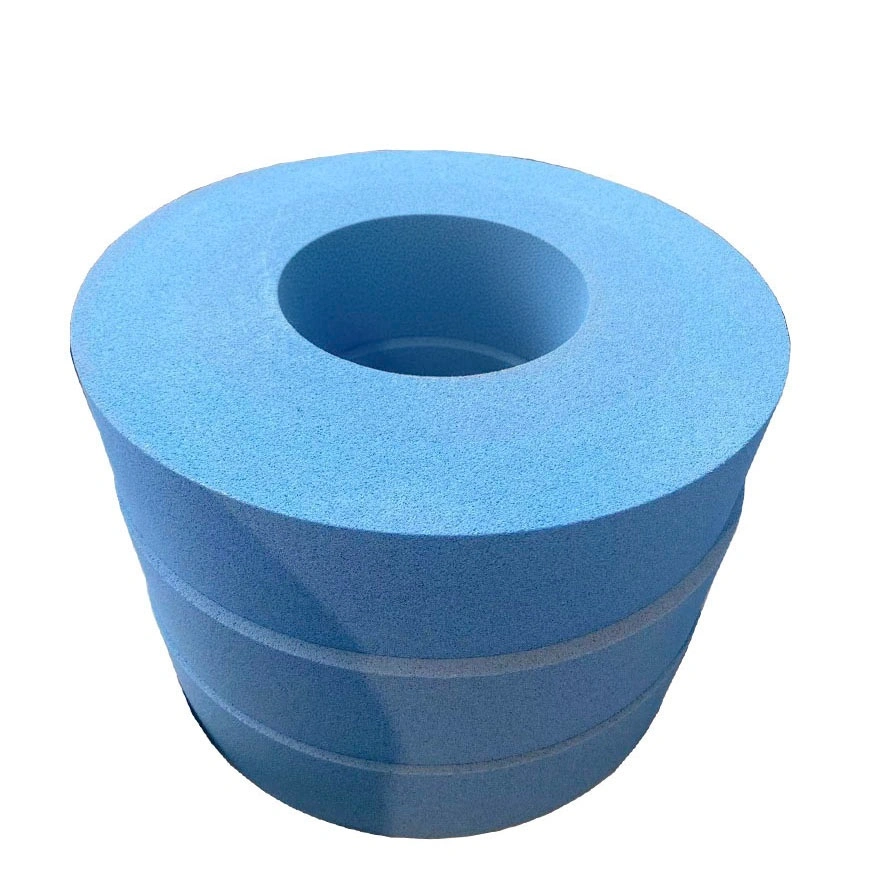

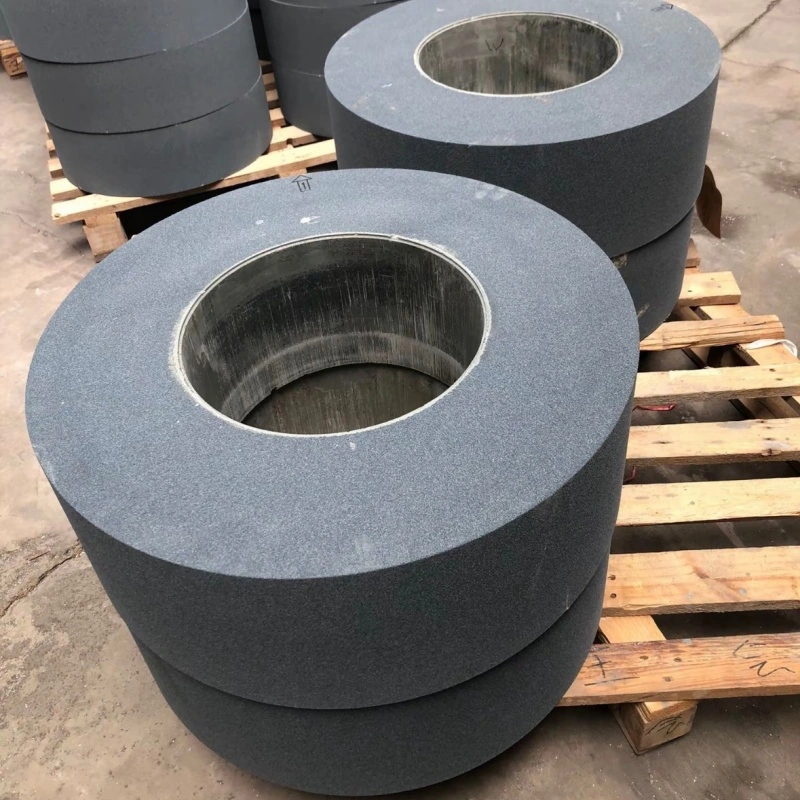

Roll Grinding Wheel

Product Description

The roll grinding wheel is manufactured with a reinforced structure and carefully selected abrasives to handle high grinding pressure and large contact areas.

Moreover, its optimized bonding system ensures excellent wheel strength and shape retention, which helps maintain precise roll profiles during grinding.

In addition, this roll grinding wheel delivers consistent cutting performance with controlled wear. As a result, operators can achieve stable surface quality while extending wheel service life.

Because roll grinding often involves large-diameter workpieces and continuous operation, this grinding wheel provides reliable thermal stability and smooth grinding behavior.

Furthermore, the wheel performs effectively on forged steel rolls, cast iron rolls, and alloy rolls, making it suitable for both rough grinding and finishing processes.

Typical Applications

This roll grinding wheel is commonly used for:

- Steel roll grinding and reconditioning

- Mill roll and work roll grinding

- Backup roll and industrial roller grinding

- Roll surface finishing and profile correction

- Maintenance of rolling mill equipment

Therefore, it is widely applied in steel mills, rolling mills, heavy machinery manufacturing, and maintenance facilities.

Available Specifications

To meet different roll grinding requirements, we offer flexible specifications:

- Diameter: 400 mm – 1,200 mm

- Thickness: 50 mm – 150 mm

- Bore size: 127 mm / 203.2 mm / 304.8 mm / Custom

- Grit size: 24# / 36# / 46# / 60# / 80#

- Bond type: Resined (B)

- Hardness: Medium to hard, suitable for heavy-duty roll grinding

In addition, customized roll grinding wheels are available according to roll material and machine conditions.

Key Advantages of Roll Grinding Wheels

- High material removal rate for large rolls

- Excellent shape retention and profile accuracy

- Stable grinding performance under heavy load

- Controlled wear and long service life

- Suitable for continuous industrial operation

As a result, users can improve roll surface quality while reducing grinding downtime.

Packaging & Shipping

Each roll grinding wheel is securely packed in strong cartons.

Moreover, cartons are placed on pallets and properly fixed, making the packaging suitable for heavy-duty products and long-distance transportation.

Customized packaging, pallet size, and labeling options are available upon request.

Related Grinding Solutions

We also supply grinding wheels for other heavy and precision grinding applications, including:

- Cylindrical grinding wheel

- Surface grinding wheel

- Vitrified bond grinding wheel

- Grinding wheel for repair workshop

These solutions help customers cover a wide range of grinding requirements.

Why Choose Our Roll Grinding Wheel

With extensive experience in supplying roll grinding wheels for steel mills and industrial users, we understand the challenges of heavy-duty roll grinding.

Therefore, we provide reliable products along with technical support to help customers select the most suitable grinding wheel.

Call to Action

Looking for a reliable roll grinding wheel for steel mill or industrial roll grinding?

Contact us today to get technical recommendations, pricing, and customized grinding solutions.