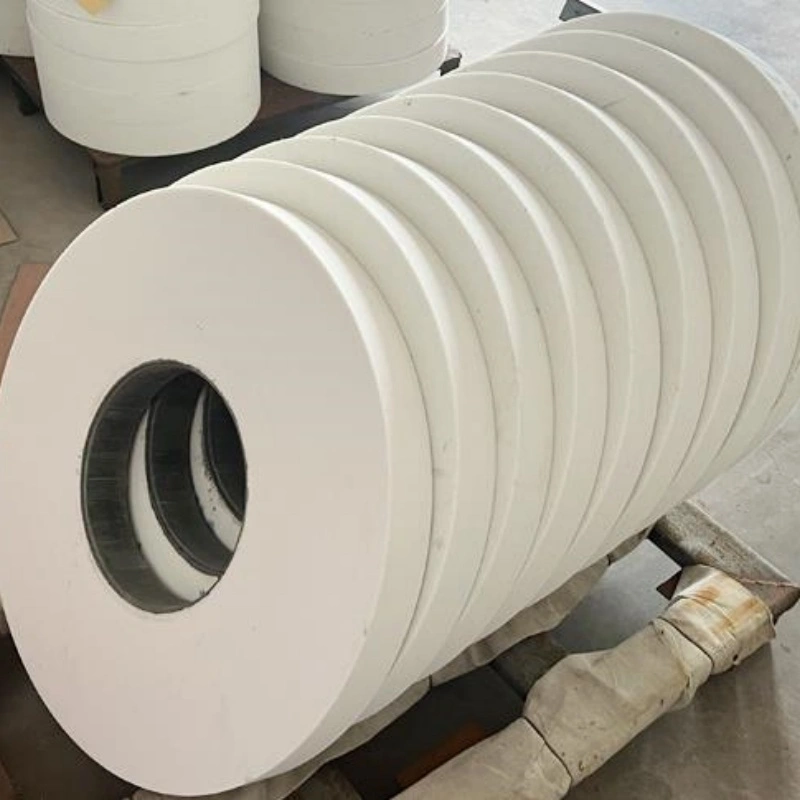

White aluminum oxide grinding wheels (WA grinding wheels).

Due to their high purity, high hardness, and good self-sharpening properties, they occupy an important position in metal processing and precision grinding.

This blog will introduce the main uses and industry application of white aluminum oxide grinding wheels to help you quickly determine if they are suitable for your processing needs.

I. What is a White Aluminum Oxide Grinding Wheel?

The firstly, white aluminum oxide grinding wheels are made from WA abrasive (White Aluminum Oxide), after high-temperature melting.

Compared to brown aluminum oxide grinding wheels, white aluminum oxide has:

1.Higher purity (Al₂O₃ ≥ 99%)

2.Sharper cutting edges

3.Better self-sharpening properties

4.Less heat generation, less likely to burn the workpiece

5.Therefore, white aluminum oxide grinding wheels are particularly suitable for grinding processes with high requirements for surface quality and machining accuracy.

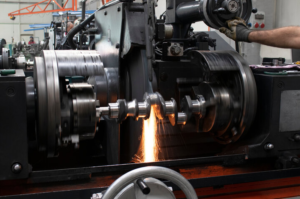

II. Main Applications of White Aluminum Oxide Grinding Wheels

Here are the following applications of WA grinding wheel:

1.Quenched steel

2.Alloy structural steel

3.Tool steel (e.g., SKD11, D2, H13)

4.Moreover, they support external cylindrical grinding, internal cylindrical grinding, and surface grinding, helping reduce grinding burns while improving dimensional stability.

5.In addition, white aluminum oxide abrasives resist dulling, which extends dressing intervals and further enhances tool edge quality.

III. Common Specifications and Forms of White Aluminum Oxide Grinding Wheels

1.T1 Flat Grinding Wheel (Surface Grinding Wheel)

2.Single-sided Concave Grinding Wheel / Double-sided Concave Grinding Wheel (Type 5 / Type 7)

4.Cylindrical Grinding Wheel

5.Internal Grinding Wheel

Common grit range:

WA 46 / 60 / 80 / 100 (roughing to finishing)

IV. How to Choose the Right White Fused Alumina Grinding Wheel?

When selecting a grinding wheel, it is recommended to focus on confirming the following parameters: Workpiece material; Grinding method (flat surface / external diameter / internal diameter); Grinding wheel outer diameter, thickness, and hole; Grit; Bond type (Resion Vitrified, common).

HTF Materials can customize white fused alumina grinding wheels according to working conditions.